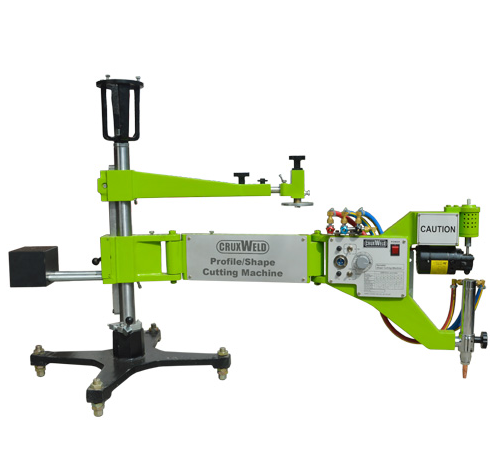

Profile Cutting Machine

The world of metal fabrication always remains in the need of gas cutting machines. The continuous need for the improvement and development in the equipment taking place to make the equipment more accurate, less time consuming thus making the businesses more profitable, less in cost and time. This machine is a precise, quality shape cutter for high production. The equipment is simple and compact and excels at repetitive work and continuously produce an accurate flame to follow the steel template. A strong and powerful magnet roller guide very smoothly the cutting torch around any shape and can cut steel up to four inches of thickness. It may be called a profile radial arm oxygen machine for cutting. The equipment is light in weight and portable and needs minimal space. It can be easily carried to the worksite and can be used by placing directly on the plate to cut

The gas profile cutting machine is a magnetized machine by a solenoid coil which is being driven by an electric motor. The steel template of any shape guide by its edge cut the desired profile with the help of cutting torch. There are stable step-less speed variation and very smooth running by SCR control. The free and frictionless movements of arms are achieved by thrust ball, needle roller bearing available in rotating joints of profile cutting machine. The easy and smooth movement of template and cutter in the vertical and horizontal direction is established by an efficient design of rack and pinion system.

Principle of Gas Profile Cutting: The sample needs to first preheat with ox fuel flame to ignition temperature. Once the temperature is reached the cutting oxygen stream in pure form directs towards the preheated metal to cut the metal by ignition at the temperature of 1600 F. The hot metal is directed by pure oxygen jet to form ‘ kerf’ at the narrow zone. The movement of flame and oxygen together at a specified speed to achieve a constant and regular operation.

Features:

- The profile gas cutting machine is lightweight, robust and portable which occupy a very little space so can be used for field job as well.

- The arms of the machine are pantograph type to keep the hinges point parallel for all the arms.

- The direct line of the guiding system is thereby tracing roller and torch.

- The machine enables torch to copy any shape offered on a template and bevel up to 45 degrees.

- It can cut any shape like a straight line, triangle, square, rectangle, stars, and hexagons.

- The electromagnetic head moves around a template and can move clockwise and anticlockwise.

- The machine accurate and easy to operate.

Components of Profile Gas Cutting Machine:

- Oxyfuel Cutting System – It consists of a cylinder of acetylene, oxygen, two regulators, two hose pipes, cutting torch with nozzles, The cutting system needs controlling of the pressure for the cutting of required pattern of the metal.

- Two Arms – These arms are connected with each other by rod and two ball bearings to give the smooth movement without any friction. The arms are moving to guide the profile shape to move around the magnet and make the cut.

- The Roller – The magnetic roller follows the shape of the template and guide the torch accurately. The roller is magnetically attracted toward the template.

- Square Base – This balance the weight of the structure and have the levelling arrangement as well.

- The Column – The central rod on which arms fixed and bush for the template is fixed with the rod or main column for the movement.

- Template – The required template should be cut in a required shape from an iron sheet of minimum 3 mm thickness.

Hi, I am interested in your pattern cutting machine. Do you have agents in the UK and how much do they cost please?

Cruxweld team thanks you for the inquiry. We will do the needful.