5 Best Spot Welders in 2024 – Reviews, Comparisons & Buyer’s Guide

If you are working with metals, a condition may surface when you need to join two metal sheets in conjunction. In such a circumstance the spot welder arrives in the scene.

Two overlapped metal pieces joined with pressure application and heat. This heat is the result of resistance to electric current at the electrode level. The metal thickness from 0.02 inches to 0.118 inches can be spot welded.

The steady pressure of the electrode results in a stable spot welding.

The basic need for the spot welding process includes a welding power source, weld head screwed with the electrodes. The electrode material may vary and comprise copper, molybdenum, tungsten, and its alloys. The size and shape of the electrode have a bearing on the result of spot welding.

We will try now to develop a buyer’s guide to answer the question, which spot welder will you pick to procure?

The market is flooded with a wealth of different spot welders. It is wiser to have an elementary knowledge of the equipment which we will diffuse in this article.

We will consider the features, technical specifications, and endurance of the spot welders obtainable in the market. Challenge is there to choose the right tool for the job.

Getting the know-how of these types of equipment makes you wiser to deal with salesmen selling skills and enthusiasm.

Spot welders are an engineering tool, which needs to join small pieces together. This professional tool is used by a professional welder or DIY with equal ease. It is not difficult to learn about spot welding or welding in general. You can acquire excellence with your untiring efforts.

It is advisable to learn the spot welding process under the able guidance of a trained professional to acquire the correct skill in welding. The safety specifications in welding remain of paramount importance always. Precautions required for the welfare of the user, environmental safety, and better welding grade.

Most of the spot welders have as simple design as they are made for one function only. We have tested and examined the available list of spot welders in the market used by hobbyist DIY and professional welders.

The following five-spot welders we have picked for the study & comparison.

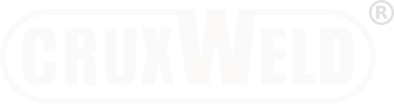

1 Cruxweld Battery Spot Welder – Pneumatically Operated (CLB5P)

Specifications

- Input supply AC 220

- Frequency 50/60 Hz

- Phase 1

- Duty cycle 50%

- Welding thickness 0.03-0.45mm

- Maximum available current 3600

- Air-cooled

- Weight 118 kg

- Dimension 1475mm x 860mm x 1350mm

Pioneer in lithium-ion battery tab manufacturing in India. The spot welder is air or pneumatically controlled arms. As per the recent trend, more and more people are looking for a customized battery pack.

The budget and quality of this welder make it a genuine option to shop this battery tab spot. If you are planning to buy a high-quality welder then this is worth your investment.

They lace the equipment with a dual pulse feature for the clean welding. The repetitive welding with clean welding is the requirement which this welder can fulfill. The strong welding of lithium strips is a probability with this machine.

They design the dual pulse to produce a neat, clean, and strong welding. The first pulse is there to clean the sheet from the impurities and oxide. They create the machine with the first weld failure stop. If there is a failure in the weld by the first pulse, then the welder will cease automatically. The first pulse works on the metal and cleans the metal. The pressure of the electrode deforms the metal in such a design to make the proper and complete contact with the electrode. This action of the second pulse will yield a stronger weld.

The battery application of spot welding includes battery pack assembly, custom battery pack, rebuilding battery pack, tabbing battery cell, alkaline weld, lithium type cell formation. The welding applications used in two configurations, opposite, and in series. It keeps the way of construction in the application simple. The force adjustment of the electrode with the metal is accurately set for a better result.

The spot machine is powerful, sturdy, and ergonomically balanced. The electrode holder and earthing clamp bear the wonderful quality. The weld time here is adjusted with a micro controller for accuracy. It can reduce the current for the thinner metal. The welder is easy to move as it is mounted on wheels.

The intelligent welding function of this spot welder can enhance the efficiency of the battery pack assembly. They lace the equipment with built-in temperature sensors and cooling system to work automatically to maintain the internal temperature.

Positives

- Strong weld

- Duty cycle 50%

- Dual pulse mode

- Microcontroller temperature adjustment

- Aesthetic weld

- Can weld up to 150 welds/min

- Strong and sturdy equipment

- Ergonomically designed welder

Battery Spot Welder – Working Video

2 Stark Professional Portable Spot welder

Specifications

- Input Voltage – 120/240

- Output – 2.5kva

- Ampere – 13.5

- Throat – 6 inches

- Duty Cycle – 50%

- Dimensions – 18-1/2″L, x 4-1/2″W. x 7-1/2″H.

- Weight – 29 pounds

- Weldable metals – uncoated mild, galvanized, stainless, mild steel up to 1/8inches sheet

This single-phase, portable air-cooled spot welder makes easy weld with a wide range of metal. The Stark Professional spot welder makes a quick, strong, spot-on a broad section of metals. It may include steel, cast iron, uncoated mild steel, stainless steel, and galvanized stainless steel. They design the welder such that inserting the metal to be welded remains a simple task as a child play.

The pressing the lever and welding technique is unique and makes it possible to complete a sizable amount of work in a brief time. The mobility of the equipment is maximum with pick and go because of a handle attached at the top of the machine. We can transport the hand spot welding machine to different job locations easily. We can complete many jobs at one time at different locations.

The spot machine is very well designed for user-friendly equipment. The welder can be used by a beginner and trained professional welder with identical ease. Ease of operation and its price tag make it a choice for beginners and DIYers.

The safe and easy spot welder to use by anyone. The quickness with clamping and releasing facilitates to apply the right amount of current and time for better spot welding process. The air-cooled function helps the welder to avoid any overheating during the functioning.

The Stark supplies you an additional pair of an electrode with the spot welder. An easily changeable electrode is firmly locked with the arm. This six inches long electrode press tightly against the material that requires to weld, leading to a powerful bond of spot welding. Removal of the tip is very easy by twisting off. When you need to replace, then rotate to restore it.

The professional build and design of the solid base of welder help to impart the reliable bonding of every spot on the metal sheet. It can easily weld a range of material up to a thickness of up to 0.12 inches. As this is a single-phase machine and runs off of 110v, you can plug this welder in any of the sockets available. They can spot on mild steel, galvanized steel, stainless steel, and cast iron as well.

Positives

- Single-phase machine

- Easy operability

- Quick press and release of the lever mechanism

- Can spot a good range of materials

- Durable and sturdy design

- Portable for many locations at a time

- Replacement tips available

- Best quality weld

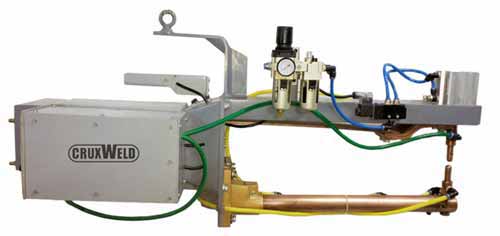

3 Tooluxe RIDGE10915L Professional 115 V Electric Spot Welder

Specifications

- Input power – 115V at 60Hz

- Input capacity – 6.6kw

- Output – 125 Amps

- Duty cycle – 30% at 6.6kw

- Weight – 34 pounds

- Dimensions – 20.5 x 6.1 x 10 inches

The Tooluxe welder is a portable spot attached with a handle. Although it weighs about 34 pounds but can be shifted from its place easily. This makes it a very stable but portable spot welder. This extra weight of welder tire you, but it suits your portable jobs in the countryside. You can handle multiple jobs at the same time and improve your business aspects with this welder.

This spot welder is versatile and can weld a wide range of metals in the welding jobs. The range is from carbon steel, galvanized steel, stainless steel, and cast iron.

The Tooluxe professional welder proves to be an easily operable spot welder. It is a preferred choice for the novice and DIYers because of its easy operation. It is again a choice for the trained professional welders as the outcome of the welding is unmatchable. The hobbyist, DIYers, and professionals opt for this welder with equal interest.

The machine is a single-phase and can be used in the home environment by hobbyists, beginners, and DIYers. It is a very safe machine to operate as long as you follow all the safety parameters. It is a novice-friendly machine as the installation and operation are effortless.

The Tooluxe people are particular about the neat build, solid, and sturdy body of the welding machine. They have a plan to supply a strong, heavy-duty, and durable machine. They keep the ergonomics in their mind at the time of the manufacturing of this machine.

The electrode tips which they supply with this welder are specially designed and comprise copper, tungsten, and molybdenum alloy. They are designed to deliver reliable welding connections. They weld up to 0.039 inches safely. The tip of six inches maintains a constant grip and strong enough pressure to make a robust bond of welding.

The tool is perfect in shape, size, and designs to deliver quick, strong, stable, and on-time welding results. This is a complete package value for your money to finish your project always in time with excellent results.

The Tooluxe is ideal for all-around welding in the resistance process. They conveniently work for the heavy-duty jobs on a lengthy series of materials. The operation of this welder is simple to follow by anyone, makes it a universal choice. Available at welding machine online e-commerce platform.

The spot welder of Tooluxe is a preferred judgment with a beginner and welding giant with equal passion. Effortless operability and installation make it an easy and early solution for their welding needs, where the quality of the welding is the prime importance. It is equally loved by DIY hobbyists and suitable for their needs. Though the machine is slightly hefty, we can bring it along from the site once carried out the job and shift the welder to a new site.

The solid and robust spot welder is designed in such a manner to offer you a best quality joint and fast enough to complete your job in stipulated time. The rapid press and release of lever make the equipment to weld quickly, thus saving them time and money. The magnitude of the pressure of the electrode gives a secure joint.

The Tooluxe welder provides us with a strong and lasting weld of metal sheets. It is not difficult to weld stainless steel while we can weld carbon steel and mild steel easily. Not to forget that it can weld uncoated galvanized steel metal sheets.

Positives

- Strong and sturdy body

- Good design match ergonomically

- Easy to handle, install, and operate

- Strongly fastened electrode tips

- Continuous strong pressure from the electrode

- Work for many different metals

- All-around quick, and good operation

4 E-bike Battery Packs Spot Welder

This battery pack system includes the following:

- Weld power supply, capacitor-discharge precision resistance, dual pulse

- Welding head

- Power cables 2pcs

- Weld head connection cables switch

- Electrodes 3mm

- Pedal Footswitch

Specifications

- Dual pulse power supply

- LCD display

- CD 300watts/second joule

- 110VAC, 208-230VAC, 50/60Hz

- Welding thickness 0.05-0.6mm

- Weight 37.5kg

- Dimension 500mm x 250mm x 346mm

It is a unique dual pulse battery tab spot welder. It has an energy locking function to ensure that power supply fluctuations shall not have any decline in the welding quality. The energy storage is 300 watts/second joule which is effective for precision metal welding.

The dual-head pulse welding promotes weld quality and reduces the spatter effectively. In two pulse welding the first pulse is for the surface coating/ oxide removal. The electrode remains in contact and deformed the metal surface a little to make effective contact with the electrode. Now the second pulse can make a proper metal weld.

The equipment comprises an auto stepping function and can achieve the preset welding parameters automatically. Suppose there is weak welding with the first pulse, then welding will stop here for second pulse welding else you change the location/condition.

The battery spot welder is equipped with a high precision microprocessor for stable repetitive welding. This will improve the quality of welding and reduce the welding spatter. There are remote welding specifications for automation. There is an inbuilt current, voltage, power monitoring, each spot quality reporting feature. The built-in welding counter calculates the solder joints in a particular time and stores them as memory. The weak welding blocking the second pulse reduces the welding scrap effectively.

Positives

- High precision microprocessor

- LCD display

- Move by air or foot pedal

- Stable, strong, and sturdy battery tab welder

- Can weld up to 0.05mm- 0.6mm

- Weak welding stop function

- Auto stepping function

- Welding counter to count effective weld

5 Sunstone’s Battery Tab Spot Welder CD400DP WH2125A

Specifications

- Dual pulse CD spot welder

- Power 200watts/400watts

- Weld head WH2125A, WH2125M Series/parallel weld head

- Footswitch

- Microswitch & cable

- Electrodes

The battery pack building is the trend now. People are welding a thin nickel tab with one battery to another, making a pack of battery. They get a higher quality of battery pack with high-grade cells for less money, growing interest in economical gain.

Sunstone Engineering offers a CD40 watts dual head spot welder with weld head WH2125 the best combination for battery pack manufacturing. The machine is very strong and sturdy with double pulse mode. The dual pulse helps to provide a strong, clean, repetitive welding.

The first pulse is very important as it will clean the surface from oxide and impurities. The first pulse will deform the surface a little to make complete contact with the electrode. The second pulse is there for the strong metal join with the battery head.

The battery spot welder is equipped with a feature of a weak welding stop function. In this function, if the first phase of the pulse will not create a proper weld then the welder will cease automatically. The process only can restart once you change the place or process.

The most popular combination for battery tab spot welder is CD400DP and the WH2125A. The power source fine-tunes the welding energy for nickel tab welding from thin to thick size. The weld head provides a controlled weld pressure from 3-15 pounds. The weld head can work manually or pneumatic operation.

Applications

- Battery pack process welding

- Thermocouple process welding

- Automotive applications of welding

- Copper, brass, and aluminum thin sheet weld

- Cross wire welding process

- Honeycomb tacking

- Resistive other applications

Positives

- Dual pulse removes contaminants

- Can weld up to 156welds/min at 40ws

- Interface, intuitive

- Single or dual pulse facilities

- Strong weld

- Aesthetic weld

Spot Welder Shopping Guide

Now it is time to make a synopsis of information before you pick a spot welder. You may keep the following points in mind before you pin on the choice of your spot welder. You will shop a welder to fulfill your need with the best of its price.

Warranty of welder

Important here to look into the warranty part of the welder. The warranty and period of a warranty need to be considered as you may not feel cheated in case of any breakdown.

Price and payment terms

This is the foremost reason to buy or skip buying the brand. It is better to budget the project and pin your welder as per the allocation and welding needs of the project. Most of the welders are worth the money you spent. Payment terms sometimes may be equated in a period to help you.

Weld quality and manufacturer’s credibility

The weld quality is the first and only consideration before choosing a spot welder. The credibility of the manufacturer for the quality of the machine and welding result is mandatory.

The whole thing you ought to know about spot welding

As you will now purchase a spot welder, it is now essential to know everything about spot welding.

What is a spot welding & how it works?

Once you own a spot welder and begin to work on it, you must be versed in the spot welding process. You have two metal plates to combine and make a thicker sheet to work on. The spot is resistance welding where the resistance produces heat at the electrode end.

The heat is the end product of the electric current passage through the electrode. The thermoelectric heat applied to the circular point on the metal sheet in the electrode’s shape. The heat with the pressure of the electrode on the workpiece leads to the joining of the surfaces on cooling. The spot may vary from 3-12mm diameter depending upon the pressure and type of the welders. It creates the electrode with an alloy predominantly copper, molybdenum, and tungsten.

These welders are useful for automotive industries, bigger manufacturers, and hobbyists as well. It is quite a favorite for metal artwork. The jewelry and ornaments also seek spot welder assistance.

Metals suitable for the spot welding process

A string of alloy and metals can be spot welded when working on sheet and wire mesh. Low carbon steel, nickel, titanium, and stainless steel alloy works well for spot welding while stainless steel has high electrical resistance and low thermal activity and becomes difficult to spot weld. High carbon steel metal and alloy become difficult to spot weld and become brittle when welded and prone to cracking.

It is a challenge to spot weld metal with low electrical conductivity. The metal like aluminum, galvanized steel, and zinc need higher current.

Terms used while doing spot welding

- Docking – Putting two metal sheets between electrodes

- Welding – When the pressure applied to the two sheets

- Forging – When you hold the sheets together

- Release – Push the electrode away from plates

Advantages of Spot Welding

- Reliable, superb, and durable weld

- No need for any extra material and filler as a power source is enough to generate heat

- No burning and stress of the base metal

- Easy to learn art.but you ern perfection before working on your project.

- Popular for its fast speed

You may also like other welding machine we have recently reviewed:

Best Welding Machine Brands In 2020 [Top 10 Amazing Choices]

Top 5 Stud Welder Brands in 2020

10 Best Plasma Cutters 2020 – Reviews And Buying Guide

Best Engine Driven Welder Generators

Frequently Asked Questions

What safety measures to observe while doing spot welding?

Utmost importance is to read and follow the safety instructions and operational guidelines. The manufacturer always supplies you with the operational guidelines booklet which is to follow religiously. Manufacturer guidelines are the best safety tool with the user to make the proper weld.

The electrode of the spot welder will transmit heat and may cause you a burn.

The safety gloves become an essential article from the safety kit. The arms of the spot welder should be cool by the water cooling/air cooling methods before the next use. The spatter and sparks are a new normal with a spot welder.

It is advisable to make sure that the user is using all the precautions. He should use eye and face protection. Never look into the light that is produced by welding procedure.

Can the electrode get stuck in spot welding?

Electrode in spot welding may get stuck calling it an electrode sticking and surface splash. The cause for this stuck may be too much heat between two materials likely to be welded. Misaligned electrodes and too low a force may cause sticking of the electrode. This sticking may result from the dirty /contaminated electrode or the metal surface. It is possible to avoid sticking by cleaning the metal and electrode.

Is it possible to check weld quality?

Analyse the alloys to be welded judiciously to make the setting on your power source. At the completion of the wielding a destructive test with a forked chisel and hammer unbuttoning is done. This will test the strength of the spot welding. If the two metals go apart quickly, it is a weak weld while making a hole in metal means a good and strong spot welding.

Can you use a single side spot welding machine?

The limitation with rocker arm type spot welder is unreachable to all areas. A single-sided spot welder can reach the inaccessible area. This is useful for the application where cosmetic looks are the prime consideration. It is not a substitute for structural welding. The area where cosmetic touch up is required the single-sided spot is the preference. The double-sided spot is advisable whenever possible.

Any additional precautions to take when spot welding?

You may add corrosion protection to two metals before the welding process. The deadeners like bonders and sealers can do the job. The primers and finishing coats should include as protection.

How do you extract a spot weld battery tab?

Once the cells are removed then comes the turn for nickel removal. Keep cool and do not force. Gently grab the nickel plate and rock the vice grips against the top of the battery and pull off the weld from ends. A pair of vice grips is a better tool to do the job.

Final Thoughts

By this time you are infused with a sea of knowledge about spot welder. You are in a position to choose welder as your need for the project. When you are looking for a spot welder, you want something easy to operate and pocket friendly. The welder should make a quick and clean weld every time. The spot welder design, its safety norms, and ergonomics are other parameters to look in. The decision to buy a welder depends upon the utility of it in the project.

We have discussed a long variety of spot welder but Cruxweld spot welding machine is choice with most of the people. The machine is a single-phase with the best clamp system.

This is a favorite welder because here you create weld in different mediums without any cumbersome intricacy. Just put your metal in the prongs, press the lever, the machine will do the rest. We are fans of the fact that we could easily replace the tips of a welder to increase its durability.

You are open for questions. Now it’s your turn to ask me or place your comments and suggestions in the box.