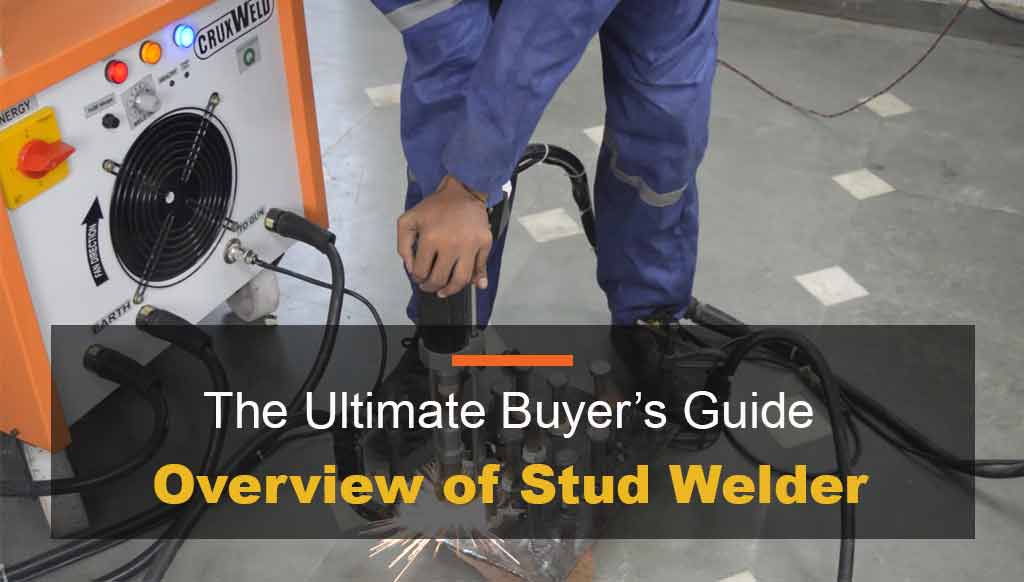

What is stud welding and how it works?

Overview of Stud Welding

Stud welding refers to a joining process of circular-shaped studs with a flat metal piece by using a welding arc and application of a pressing force. The surfaces joined in the liquid state with no filler material.

It is a fast, simple, and accurate welding process which combines two identical or different metals with no consumables. The fasteners are in diverse categories as threaded, untreated, taped, and have different sizes depending upon the demand of the customer. The base metals and studs may belong to the metal category as carbon steel, stainless steel, alloys, and aluminum. The joining of the two surfaces happened with heat and pressure.

Stud welding carries a flag of reliability and promptness. Many industries and applications are allotted exclusively to them. Here we will make a guiding synopsis of the stud welding process step by step.

Major Benefits of Stud Welding

- The process is widely accepted for the appearance of the welding joint as there is no mark on the opposite side of the workpiece.

- The adaptability is at the peak with stud welding as it is possible to weld with any type of stud, threaded, unthreaded, and internally threaded. The metal of the workpiece and stud may be of carbon steel, stainless steel, copper, and aluminum.

- Stud welder works on one side of the metal. It makes the user comfortable as he will not contort for the welding.

- No, any hole is made in the workpiece before welding.

- Clean, rust-free, leak-free welding process.

- Joint is stronger than the parent base material.

- Novice in welding can operate the equipment with ease and excellent results

- Economical process for the fast speed of joining studs and welders skills.

- Possible to use in automation for major fabrication.

- The shape of the parent metal remains unaltered.

Two Types of Stud Welding

It is a useful procedure that does not need a traditional way to install a fastener on a workpiece. No need to make a drill hole in stud welding. The heat of the arc melts the surface of fastener and base metal. The fastener is manipulated to the surface of the workpiece in the right position. When this fastener and the base metal cool, it will join to the base metal.

There are two primary types of stud welding, drawn arc stud welding, and the capacitor discharge. Here the base metal and fastener get heated by an electric arc where the fastener acts as an electrode to produce an arc between electrode and base metal. The strong arc melts both, and pressure with cooling makes a reliable joint.

The capacitor discharge does not require the flux, and it is a faster, and more efficient stud welding process. It is as fast as to weld studs in 1-6 milliseconds.

Drawn Arc Stud Welding

It is a more versatile and adaptable method when welding material and diameter has a good range. It can work on thick melt up to 2mm and even on a rusted or coated material. It is absolutely suited for studs of larger diameter. There is an option to set the current and weld time according to the size of the stud and metal sheet.

Once you place the stud on the base metal, create a pilot arc from the electricity. Lift the stud to preset height to create the main arc which will lead to welding of the tip of the stud and base metal. The stud gun now pushes the fastener to the base metal and holds there till cooling. A ceramic ferrule may hold the stud in its place, which can be chipped off once the process is completed.

There is a range available for the drawn arc stud welding. It depends upon the size of the length of the studs. We have to choose the stud welder for any application to know its accessibility and project. The base of stud diameter, welding rate, and thickness are the factors to consider before choosing a stud welder.

Advantages of Drawn Arc Stud Welding

- It joins the surface of the stud with metal sheets in the entire length, thus making the welding uniform and high in quality.

- Drilling, riveting, is removed completely in this process.

- No need for any flux, inert gas during the process.

- A versatile process where the diameter of 2mm to 25 mm stud can be fastened.

- Novice welders can do the job as this is a simple process.

- A Useful process when high weld strength is required.

- The scaly and greasy parent metal is possible to stud weld with this process.

- Structural formation for the stud drawn arc process.

- A drawn arc welding machine can join the bigger size diameter.

Applications of Drawn Arc Stud Welding

- The industrial transformer which needs a strong fusion can be structured with a drawn arc easily.

- Constructing a boiler can not be completed without drawn arc stud welding because of a strong weld joint which results from this equipment.

- The automotive industry where such a process is required in power steering, dashboard, fabrication.

- Heat exchanger creation is possible with stud welding machines for commercial use.

- Shipbuilding is the application a drawn arc welding process can do very well.

- Heavy fabrication and structure creation is done by this stud welder.

- It can achieve bridges and the joining of a bridge with a road with stud welding. The strength of the joint is at its best.

Capacitor Discharge Stud Welding

The capacitor discharge welding process is highly acceptable for instances where the need for weld joints is flawless and no reverse marking. The appearance of the welded metal is very important with CD welding. It is best with a clean and flat base metal of mild steel, stainless steel, and aluminum.

The CD welding is specially designed for a thin metal of 0.7 mm thick. This restrictive type of process is suited best for thin metal studs for reliable welding. We desire the base metal clean, not coated, and rust-free for the capacitor discharge welding process.

We pre set the voltage and time according to the stud and base metal thickness. Now place the stud on the sheet, the pip of the stud melts with the base metal on passing the current and changes to a molten pool. The stud gun welder pushes the stud to the melted surface area of parent metal to fuse them both on cooling.

If you plan to choose a CD welding equipment, keep in mind that stud welder needs to be lightweight, easy to use, compact, flexible, and minimum recharge time.

Advantages of Capacitor Discharge Stud Welder

- The fusion is uniform with high welding quality.

- No need for any rework on the other side as the other side is clean.

- No need for any flux, inert gas.

- Drilling, riveting, and making a hole is omitted.

- No marking on the backside of the metal

- Better for thin metal

- The small diameter of a stud for welding.

- In need of excellent aesthetics

- Leakproof

- Rust free

- In need of clean weld

- Compact, handy, and portable.

- Stud welder is having password protection and saving of the data facilities.

Applications of Capacitor Discharge Stud Welding

- Catering and food preparing industries need utensils that are useful only if they are leak-free and rust-free. It becomes easy to make food, serve, and clean them.

- A stud welding gun can do the fastening of brass nameplates.

- Badges, artwork, and jewelry where the neat and clean process is imperative.

- Microwave grills, frying pans, cookers, and other electrical appliances need the capacitor discharge process.

- Kitchenware has a different range of pots, pans, and other usable utensils in the kitchen.

- Electrical and electronic devices for communication needs a stud welder kit.

- Metal art, decorative items need a stud welder of the best quality.

Guidelines for Stud Welding

- Set appropriate weld time according to stud weld diameter and base material.

- According to the diameter of the weld base, set the suitable amperage.

- Make sure that the negative polarity is to the stud gun.

- Ensure the ground connection is completely tight and clean.

- Clean the work surface properly so that the impurities can not affect the weld.

- Keep the studs and ferrules clean and free of moisture.

- Remove the varnish, scale, rust, and plastic surfaces from the work surface and ensure that the plate surface is electrically conductive.

You May Also Like: Top 5 Stud Welders in 2020

FAQs: About Stud Welder

How does a stud gun work?

Once we place a stud with ferrule over the workpiece the process starts. Triggering the welding stud gun automatically lifts the fastener from base metal to start an electric arc. The heat of this strong arc will melt the base of the stud and metal surface together. The stud gun welding presses the stud toward the molten pool and continues to press till cooling happens. Cooling solidifies the joint and ferrule is chipped off to complete the process.

How strong is the stud welding?

The process can fasten any stud to a workpiece. Better selection of studs size and power source of welding machine make the stud welding stronger than the base metal.

Can you stud weld aluminum?

Aluminum stud weld is possible with a stud welding machine. The stud used here may be threaded, unthreaded, internally threaded. The size may vary from 2 mm-25 mm. We should choose the stud welder as per the size of the stud and metal sheet.

How are shear studs installed?

The shear studs help to increase the performance of composite beams. The strength achieved in bending, and stiffness allow the construction for a longer time span, column-free, more flexible, and better service opportunities.

Composite beams have rolled steel sections with a concrete slab. Shear studs transfer force between steel and concrete slabs. The studs normally welded to the beam through a deck sheet. The concrete slab was created to give strength to hold the stress in a better way.

What does the word stud mean?

A tiny headed piece of metal for decoration that pierce and project from a surface is a stud.

How do you break a weld?

Different types of welding require distinct ways to undo welding. The different means can be plasma cutter, grinding, circular saw, torch cutting, and drilling.

What is plug weld?

Fastening of two metal pieces by using a welder. Drill a hole in the upper piece and place the piece over the bottom piece, it places A weld bead inside the drill hole and hold the two metal pieces together.

Conclusion

The technique is the latest trend in metal structure formation. The drawn arc is the choice for heavy structure building, fabrication, deck formation, shipbuilding, and other heavy-duty welding procedures. The fine welding where aesthetic looks are the prime importance than capacitor discharge is an option. The conditions where CD is preferred are artwork, jewelry, metal art, catering vessels, nameplates, and every need where looks take a lead.

We have discussed the buying guide of a stud welder. We need to assess our project about the metal and stud size, size of the project, time for completion of the project, budget involved, and looks of the final project articles.

We are always very near to you to assist you in any manner from choosing the stud welder to completion of the project.

nice article

Awesome information thanks for sharing this

You may subscribe our youtube channel for regular update at https://goo.gl/iBfZJX

Hello

The blog you posted here is very informative. Welding is a fabrication or sculptural process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool causing fusion. Welding is distinct from lower temperature metal-joining techniques such as brazing and soldering, which do not melt the base metal.