Stud Welder

What is Stud Welding?

Stud welding named to technique akin to flash welding. A fastener or specially designed nut is welded to another metal surface, a base metal /substrate. These fastener can be of different shape and characters like threaded, unthreaded. This bolt may be automatically fed in to the spot for welding. The require weld nut generally have a flange with a small nubs which melt to form the welding joint. The weld nuts are required to use in stud welder which manufacturers create for two main types of welding like capacitor discharge stud welding and drawn arc stud welding process.

Types of Stud welding

Thee main welding process in stud are three used in a range of manufacturing process as capacitor discharge (CD), The drawn arc (DA) and short cycle (SC) Each process suited to a particular material and capabilities but all these processes are giving strong and lasting results. The process of stud welding is a useful in a divers range of industries like electrical, mechanical, decorative and different consumer industries.

Benefits of Stud Welding

- Superior welded joint strength – The process produces a welded joint which is far stronger than the stud and parent metal. The superiority is for its high quality, and reliable fastening. The process of stud welding do not weaken the material and do not produce any hole and revere marking on the metal.

- Minimal fatigue to the operator – The stud welder is designed in such a light weight, balance and compact that it does not cause any fatigue and clumsiness to the operator during the stud welding.

- Better profit of margins – The rapid welding process by our stud welder and flexibility in all applications help to save the money to the user.

- Versatile application – Our stud welder is designed such way to provide a series of results as per requirements, budget and company set up.

Stud Welder by Cruxweld

Stud Welder Machines of Cruxweld

-

Drawn Arc Stud Welding Machines

They are chosen for welding on to thicker materials 2mm and above, large diameter studs, material in imperfections like rusting, grease and curved surface. It produces a fantastic type of neat, long lasting and strong welding joint. The drawn arc stud are loaded with aluminium flux ball on the weld end which assist in welding process. These studs are commonly made from mild steel and stainless steel.

-

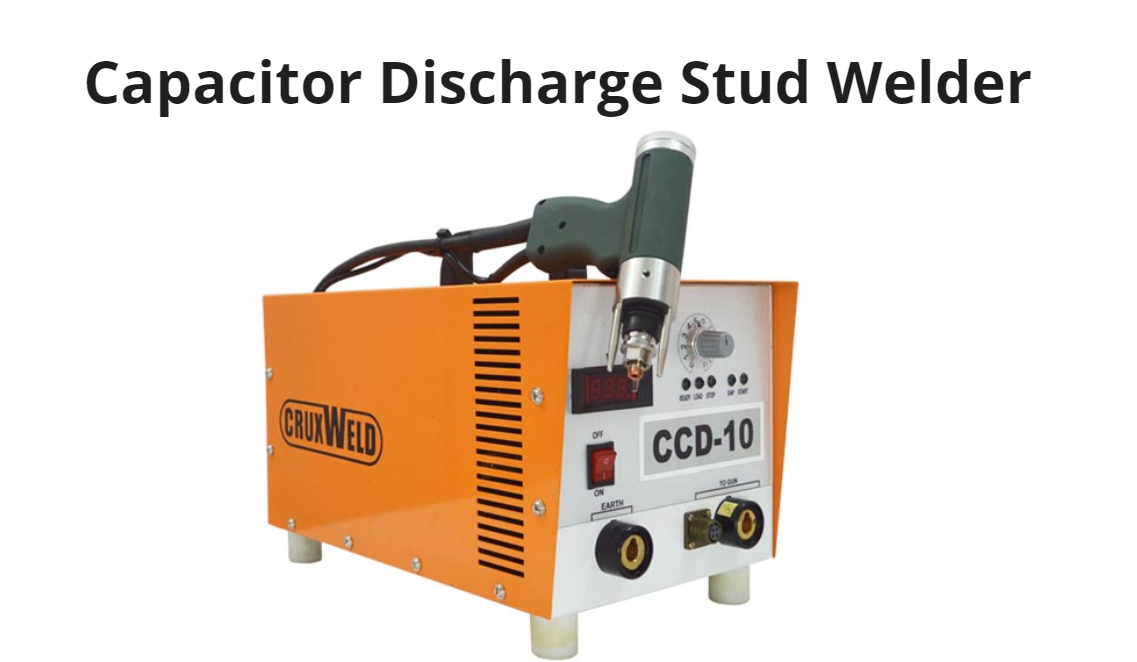

Capacitor Discharge stud welder

These are perfect to weld on thinner plate of less then 2 mm thickness with a clean surface. It is a perfect choice for aluminium, mild steel, brass and stainless steel. This equipment creates a strong weld without penetration of base metal. The tip of the weld nut serve two purposes as it act as a timing device to keep the stud away from base metal and second it disintegrate when the trigger of gun is pulled making a strong weld by solidification.

-

Short Cycle stud welder

It creates more penetrative weld than capacitor discharge, material 1.5 mm and thicker. It can be useful for rolled material and coated metal sheet. This is more tolerant of dirty surfaces and produce a strong weld joint.