AC vs DC Welding – 5 reasons which one is right for your welding job.

Although DC welding is preferred, in some cases AC welding may provide a better solution. In this article, I’m going to open it up a bit and explain why it’s important for you to understand.

If one is familiar with or working in the welding industry, one might have heard these terms AC and DC. These AC and DC are two types of current used in the welding process. The welding process uses an electric arc that initiates the heat process needed to melt the metal. The need is to produce a stable current flow having different polarities depending upon the material to be welded.

One needs to understand these two currents and how they affect the welding machine and electrodes to understand and make a good weld. We have to learn AC vs DC welding and its differences.

The AC and DC welding is taken from the polarity of the current passing through the electrode of the machine. The welding strength & quality depends on the polarity of the electrode.

Neither DC nor AC is necessarily superior. They are different in characteristics, and which type you select depends on various factors, which we will be discussing in this article to better understand the differences between DC and AC welding.

Analysis of AC welding

The alternating current (AC) flows electrons back and forth. The electrons switch at a speed of 120 times each second. Now we can say safely this AC is an alternating current since the current is ever alternating.

In most situations, AC is considered inferior for welding which makes DC the natural choice. However, this is not a universal choice and depends upon many factors which we will be discussing here further.

Instances where AC welding is superior

AC welders being cheaper than DC welders becomes a natural choice for beginners due to their price only. In the case of the exclusive availability of AC welders, it becomes an obvious choice.

The welding of magnetic materials needs AC as the only choice as alternating current makes a steadier arc specifically which can reduce the arc blow you are commonly experiencing with a DC welder.

The welding aluminum needs a very high temperature so the AC welder becomes a natural choice that generates a very stable and high-temperature arc.

AC welding penetrates deep in metal plates to make a choice of welding as in shipbuilding etc.

Shortcomings of AC welding

Even with few advantages, there are many situations where it is not the first choice of welding. The main drawback of AC welding is the continuous alternation of the direction of the current. As the current changes direction, there is a snap moment when there is no amperage.

There is more fluctuation in the arc of the AC welder, making the DC welder acceptable for its easier and clean weld features.

AC welding generates more spatter making it a poor choice for overhead and vertical welding.

Advantages of AC welder

⇛ AC machines are usually pocket-friendly.

⇛ Arc blow issues can be fixed easily.

⇛ The choice for aluminum welding.

⇛ The best bet for magnetic field welding.

Disadvantages of AC welder

⇛ AC Welders do not produce smooth welds.

⇛ The fluctuation in AC welding is more than in DC welding.

⇛ Maximum spatter in AC welding.

⇛ Arc in AC welders is very hard to work.

Analysis of DC welding

DC welding is used more commonly than AC welding and is considered far superior welding than AC welding. DC welding current flows continuously and in one direction only. The arc is constant and flawless.

This type of current is a choice in batteries, low voltage devices. The cars also utilize DC electricity.

Where DC welding is a choice

The arc in DC welding is stable as there are no zero amperage moments as in AC welding. This allows DC welding an easier way to control arc and produce clean smooth and spatter-free welding.

There is less spatter and mess in DC welding and a better choice for overhead and vertical welding instead of AC welding.

DC welding is a better choice for fresh welders. Attractive welding can be produced with very little learning. The DC is the most common welding choice.

Shortcomings of DC welding

There are situations where it is not the better choice as arc blow with DC welding is not great for magnetic materials.

DC welding does not make as high a temperature as AC welding, so it is not a natural choice for aluminum welding.

DC is a natural choice for the beginner but the cost makes it difficult for them to choose DC instead of an AC welder which is less expensive.

Advantages of DC welding

⇛ The arc here is very stable.

⇛ The weld here is very smooth.

⇛ Few spatters only.

⇛ It is easy to operate.

Disadvantages of DC welding

⇛ Expensive equipment.

⇛ Arc blow is produced.

⇛ Not a choice for aluminum.

Is DC/AC welding superior?

If we can decide definitely which welding process is better and can train you with that method for the perfect welding process. The reality is totally different as we generally live in a gray zone.

Which type of welding we should use, depends upon the situation. Each type of welding may be a better choice in different scenarios.

Aluminum Welding

AC welding is a better choice when one is welding aluminum. The AC welding here achieves a very high temperature which is a cornerstone in aluminum welding.

DC welder by its virtue can not achieve the same temperature, making it a bad choice in aluminum welding.

Thin metals welding

The lower temperature of DC welding makes it a choice of welding in thin metals which otherwise may blow the thin metal in AC welding.

Beginners or Novice

As DC welding is much easier to master the art and offers a clean weld makes it a natural choice for the novice. But the DC welder is an expensive option than to the AC welder, which may tilt the beginner toward an AC welder due to its affordable entry into the welding arena.

Deep Penetration

The thick metal of the workpiece needs deep penetration for the weld to make firm adherence. Thus making AC welding a better choice where deep penetration is needed.

Vertical and Overhead Welding

DC welding by its nature is clean, non-messy, with little spatters. The welding in vertical and overhead positions needs molten spatter free on your dome. This makes DC welding a perfect choice in these situations.

Magnetized Metals

In magnetized materials welding, the choice goes to AC since there is no arc blow here which is a common occurrence with DC welders when welding magnetized materials.

Situations for DC Welding

⇛ When affordability is not an issue.

⇛ When needed smooth and clean weld.

⇛ Thin metals welding.

⇛ Overhead and vertical welding.

⇛ Novice with little experience in welding.

Situations for AC Welding

⇛ The budget is limited.

⇛ Weld’s appearance is not a concern.

⇛ Deep penetration is needed.

⇛ Welding magnetized material.

See also…

A Guide To Aluminum Welding Process

Understanding Aluminum Welding Process Compared With Steel Welding

Difference between DC and AC welding

| DC Welding | AC Welding |

|---|---|

| The initial cost is high. | AC welding machines cost less than DC equipment. |

| All types of welding electrodes can be welded. | Bare electrodes cannot be used. Only use specially designed coated electrodes. |

| Maintenance costs are higher compared to AC welding. | Lower maintenance costs compared to DC arc welding. |

| Compared to AC, the welding output is smoother. | Weld quality is not as smooth as DC welding. |

| Stable Arc | Unstable arc |

| The heat distribution at the two poles is different [polarity]. | The distribution of heat is uniform. |

| Arc blow is severe. | Arc breakdown will not occur. |

| DC positive electrodes provide greater weld metal penetration. | Less penetration into weld metal. |

| Less spatter | AC welding produces more spatter than DC welding. |

| Straight polarity can weld thinner metals better than AC. | Not recommended for thinner metals. |

| More suitable for overhead welding and vertical welding. | Better with flat-position welding. |

| DC welders are suitable for welding all kinds of metals by changing the polarity. | Usually ferrous material. |

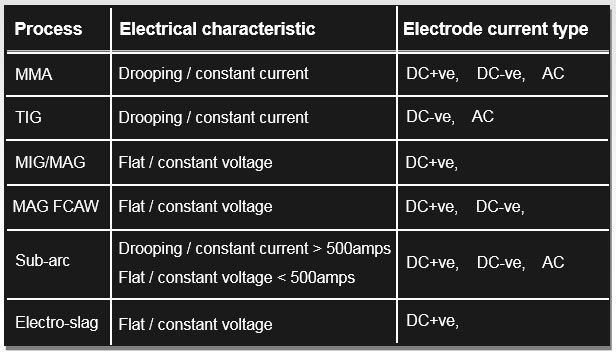

The following table is a welding process comparison of electrical characteristics:

Inference

Once we compare Alternating current (AC) and Direct Current (DC) welding, there is no definitive answer as to which one is better. Each one has its weaknesses and strengths. We feel each one is superior under certain circumstances. We should master the skill in both methods. In a situation to choose one only, DC welding is a better bet. It works on an extensive range of metals, produces smooth weld, with minimal spatter, and is easy to master but consider its cost which is higher than an AC welder.