12 Different Types of Welding Processes [The Definitive Guide]

Do you start to learn the welding process?

Are you aware of distinct types of welding processes?

Now you need to have a synopsis of the different welding processes that exist. Some are easier while the other processes are difficult to master. Few welding processes produce a clean bead and require no or little cleaning, while others produce the exact opposite.

Welding is not only constructive but an art form as well.

Constructive applications affect your daily life positively as the car you drive, your office, and where you work, happen with welding only. Different metals require different forms of welding.

To simplify the subject, we have compiled key instructions regarding twelve different types of welding processes.

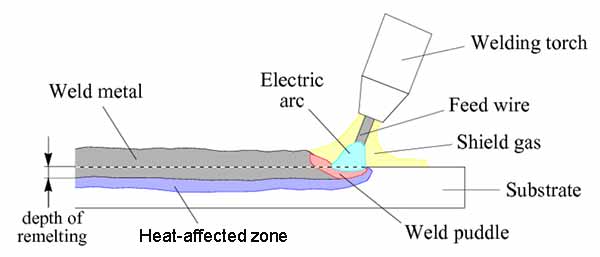

1. MIG – Gas Metal Arc Welding (GMAW)

MIG welding is a simple, popular form of welding, a novice can operate and master the art easily.

MIG stands for metal inert gas and sometimes may be called gas metal arc welding (GMAW). It is a semi-automatic, quick process where filler wire is fed through the gun, and shielding gas is expelled around to protect from environmental impurities. The filler wire is fed on a spool to act as an electrode as well.

The tip of the wire acts as an electrode to create the arc with base metal which melts as filler material to create the weld. The process is continuous and requires presetting of the parameters as per the welding need. The versatile process to weld an extensive list of metals which produces a clean, smooth, and visually appealing weld bead.

These welding types are sensitive to external factors like rain, wind, and dust making them not great for outdoor use. The quality problem with MIG welding includes dross and porosity to make the structure weak.

The commonest use of the MIG welding process is in automotive repair, construction, plumbing, robotics, and the maritime industry. The welding offered is sturdy, strong, and can withstand enormous force.

2. Stick – Shielded Metal Arc Welding (SMAW)

These are century-old types of welding processes and improve regularly from time to time. It is popular welding because of its low cost, and easy and simple operability. The process comes with spatter welding that needs cleanup, essentially.

The filler material here is a replaceable stick electrode. It generates the arc when the end of the stick contacts the base metals. The heat of the arc melts the electrode’s filler metal to make the weld. It coats the stick electrode with a flux that creates a shielding cloud to protect the weld zone from oxidation. The flux on cooling changes into slag, which needs to chip off.

The bright side of the process is that it is possible to perform the process of stick weldings outdoors and in adverse weather like wind and rain. As it is possible to weld on rusted, painted, and dirty metals so it is useful in equipment repair. The variety of electrodes available in the market, but none work for thin metals. It requires long learning before you master stick welding.

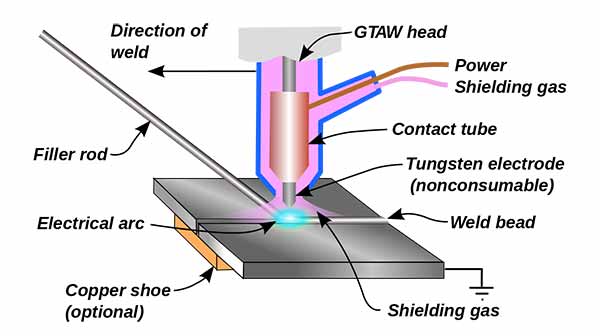

3. TIG – Gas Tungsten Arc Welding (GTAW)

TIG welding is possible with no filler material. The non-consumable tungsten electrode is used to create the arc when contacting the base metal. The strong arc melts the two metals and joins them. You may use filler wire if required. We need a constant supply of shielding gas to protect welding from environmental impurities. It works better indoors and away from the elements.

It is one of the strong welds but difficult to master. Only an experienced welder can perform this art as they use both hands in unison to perform the welding. The welding results are precise, strong, visually appealing, and require no cleanup. It is used to weld stainless steel, aluminum, magnesium, nickel, and copper with ease. The process is quite popular for industries that work on nonferrous metal as tubing, bicycles, and vehicle manufacturing. It is suitable to repair tools made from aluminum, magnesium, and stainless steel.

What is TIG Welding?

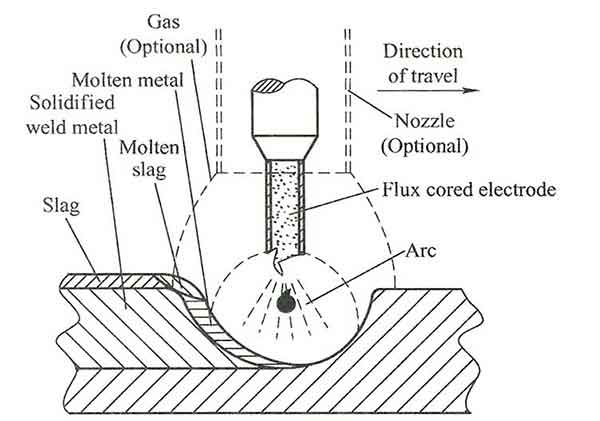

4. Flux-cored arc welding (FCAW)

FCAW is similar to MIG welding, as the power source can perform both types of welding. MIG welding needs filler wire working as an electrode fed continuously from the gun. Conversely, FCAW has a wire with its core as flux and creates a gas shielding zone around the weld. No need for any external shielding gas in this welding type. The process is versatile and works for thick metals.

The welding process is efficient and works well for heavy metals with high-heat welding. No need for any external gas makes it a choice of welding at a lower cost. It is useful for thicker metal and is used in heavy equipment repair. Before you get a beautiful clean weld, you need to do cleanup from the slag of flux. It is done with ease outdoors as it does not require a shielding gas.

5. Submerged Arc Welding (SAW)

Type of welding involves the covering of metal pieces, welding wire, arc, and welding joint by a blanket of flux. It makes the process safe as there are no emissions of welding fumes, strong arc lights, and flying slags. The flux barrier protects the human and robot whosoever is performing the welding. It is a faster process for high-production industries.

SAW produces strong welds with deep penetration, with minimal preparation quickly and efficiently. It protects the welder from UV light and infrared radiation because of the flux layer.

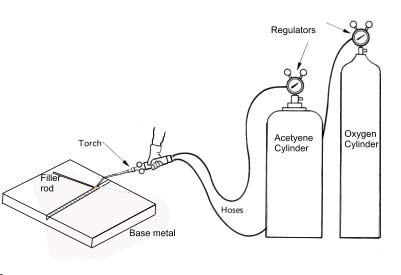

6. Gas Welding/Oxyacetylene Welding

One of the hottest methods of welding at 3500 degrees Celsius. The temperature of welding here reaches seven times as hot as the biggest, hottest pizza oven. It generates heat when a mixture of fuel gases and oxygen passes in a torch. The process involves three types of flames: neutral flame, carburizing flame, and oxidizing flame.

The advantages of the welding process are many. It is portable because of pressurized gas filled in a handy steel cylinder. It is fairly easy to use, and versatile for different sizes of metals. It is a very safe and economical option where a novice can perform easily.

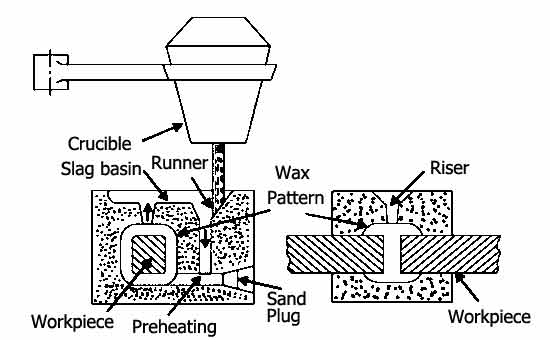

7. Thermit Welding

When thermit (a mixture of aluminum powder and iron oxide) is ignited it leads to an exothermic reaction non-violent. The excessive heat melts the metal and pours at the needed joint surfaces. The liquid metal solidifies on cooling to create a solid welding joint.

It is a simple and fast method to join similar and dissimilar metals. This welding process does not need any power supply, the only need is to heat the thermite at 1300 degrees Celsius.

8. Forge Welding

What is welding? This is the oldest welding technique when we were questioning what welding is. This technique is answering for centuries. The metal here heated to a malleable state which hammered into the desired form and finally cooled to set in the shape.

The process came into mind while a blacksmith working on metal. It is not limited to these professionals only, but forge welding happens to be a choice in the aerospace industry. The process needs a skilled user but is a popular choice as there is no need for any filler metal.

9. Electron Beam Welding

Firing the ray of high-velocity electrons at the welding metal involves this type of welding. The energy from the electron transfers to the sheets to melt the welding metals, which can be joined and fused.

The type of welding is employed in multiple industries like automated automotive parts, and high-end aircraft engine industries. This can be a useful tool in aerospace components, bimetal saw blades, and transmission assemblies. It is a perfect choice to seal electrical components. The technique is good for dissimilar metals of various melting points and thermal conductivities. This welding method is good for thin and thick metal.

10. Atomic Hydrogen Welding

The welding process is replaced now by MIG welding now in most indications. It is still a perfect choice for tungsten welding. This metal is heat resistant, but by this method, you can fuse without altering the metal when joining and welding them. They place the two metal tungsten electrodes in a hydrogen atmosphere. The hydrogen molecules in explosive heat can produce heat up to 3000 degrees Celsius. The proper safety precautions like welder gloves, suits, goggles, and helmets are essential.

11. Plasma Arc Welding

A newer technique was developed in 1954 and is similar to TIG welding. They pass the electrical current through an orifice of the nozzle protected by gases for the ultimate accuracy to weld a small area. It produces a narrow bead, pleasing weld, and strong, and speedy welding.

The method used an extremely high temperature for a deep and stronger weld. The aircraft industry uses this technique, but not of any use to hobbyists and DIY users.

12. Resistance Welding

This is a thermoelectric process where electric resistance is employed to create heat, leading to a molten state of material being joined. The efficient welding process is pollution-free with minimum electricity consumption as well. It uses two electrodes in spot welding where the tip of the electrode produces heat and fusion on cooling. The following are the different types of welding.

- Spot welding

- Seam welding

- Projection Welding

- Flash butt welding

Finishing Words

We expect now, you have a basic understanding of the various types of welding. Few types are run by simple machines while others need expensive equipment. Some can be performed by DIYs and hobbyists without spending too much. Now is the time to purchase a welder, check our guide to buying a welder.

Thank you for sparing time to read the article but your comment will help us to understand your need.

Place your suggestion in the comment box.

You might also like:

Submerged Arc Welding (SAW): Working Process, Equipment, Parts, And Its Applications

4 Best Ways For Stainless Steel Welding [A Quick Guide]

Cast Iron Welding Procedure [Step-By-Step Guide]

Arc Welding Machine Work Instructions (5 Steps To Improve Your Arc Welding Technique)

Ramakant Ji,

Need to connect with you for one of our product – unable to understand what process of welding is done on the part therefore, seek your guidance

Can you please call me directly at +919408107267

Ramakant Ji,

Unable to understand what process of welding is done on the part therefore, seek your guidance

Can you please call me directly at +919408107267