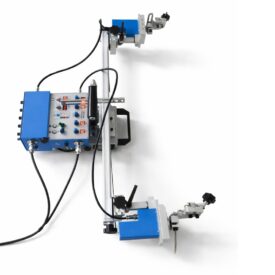

Dual torch welding carriage for long seam automation — Cruxweld DynaTwin 200M delivers trackless magnetic deployment, oscillation control, and dual-torch productivity. The Cruxweld DynaTwin 200M is a dual torch welding carriage engineered for high-repeatability fabrication where long seam welding must be faster, more consistent, and less dependent on manual travel skill. It combines two synchronized torches, controlled travel speed, and oscillation (weaving) capability in a trackless, magnetic-mount system that can be deployed directly on steel workpieces.

The dual torch welding carriage setup is ideal for long seam welding where repeatability and speed matter. DynaTwin 200M delivers the strongest results where welding work is seam-length driven and repeatable, and where seam layout supports two parallel welds in one travel run.

High-fit industries and jobs

Structural steel fabrication: box beams, I-beams, girders, stiffeners, long plate assemblies

Shipbuilding & marine: hull panels, deck structures, bulkheads, longitudinal stiffeners

Oil & gas / EPC fabrication: skids, pipe racks, platforms, structural frames, supports

Heavy equipment manufacturing: mining frames, construction equipment structures, chassis members

Bridge and infrastructure fabrication: repetitive long seams and reinforcement weldments

Export-oriented job shops: consistent bead profile and throughput across shifts and operators

If your jobs are highly variable, require tight-radius curved paths, or involve continuous 3D torch manipulation, a single-torch setup or manual welding may be the better fit. This page is written to help you decide where a dual torch welding carriage is the right production tool.

Long-seam welding operations typically face a repeat set of constraints:

Labor shortage and skill dependency: production capacity tied to certified welder availability

Inconsistent travel speed and bead profile: manual variation increases repair risk over long seams

High welding cost per meter: rework, grinding, and inspection delays consume throughput capacity

Productivity bottlenecks: manual and single-torch workflows limit line output on repetitive long seams

Operator fatigue: quality consistency drops over long shifts on repetitive work

Schedule pressure: missed delivery windows due to unpredictable throughput on long-seam weldments

DynaTwin 200M addresses these constraints by stabilizing motion variables (travel + oscillation) and enabling dual-torch coverage where layout allows—making it a practical welding automation carriage for heavy fabrication.

DynaTwin 200M is a dual torch welding carriage that runs two torches in a synchronized travel pass. In applications with two parallel seams (common in stiffeners, beams, and certain plate assemblies), this increases coverage per run and can reduce total cycle time compared to single-torch automation and manual teams.

Travel speed variation is one of the biggest sources of bead inconsistency on long runs. This mechanized welding carriage maintains controlled travel movement so the weld output is less dependent on operator travel technique and fatigue effects.

This is a welding carriage with oscillation designed to support weaving patterns where required by joint design and qualified procedures. Oscillation is used to control bead width and deposition distribution—especially on long seam work where manual weaving consistency varies between operators and shifts.

DynaTwin 200M mounts directly on steel workpieces using a magnetic base. As a trackless welding carriage, it reduces rail installation time, avoids dedicated track space, and supports faster repositioning between weld stations—useful for large plates and long structural members.

A production-friendly mechanical guidance approach supports seam following over long passes. The practical advantage: less operator micro-correction, fewer interruptions, and more consistent output on straight sections.

Dual torch welding system

Benefit: With programmable oscillation, the dual torch welding carriage maintains consistent bead profile across long runs. Two parallel welds per travel run where layout supports it, improving coverage per pass.

Oscillation (weaving) capability

Benefit: Repeatable bead profile control on long seams; stable weaving behavior versus manual variability.

Controlled travel speed

Benefit: More consistent output across operators and shifts; reduced speed-related bead variation.

Trackless magnetic drive

Benefit: Faster setup and repositioning; no rail installation; mounts directly to the workpiece.

Torch adjustment flexibility (spacing and angular alignment)

Benefit: Practical alignment to joint geometry; repeatability between job setups.

Workshop-suitable seam guidance

Benefit: Consistent seam following on straight runs in typical fabrication environments.

For related mechanized solutions, see Cruxweld’s welding automation solutions and trackless carriage references such as the Dynex 5M trackless welding carriage.

![]()

Note: The ranges below are indicative and depend on joint type, thickness, fit-up quality, WPS, duty cycle, and workflow discipline.

| Comparison Factor | Manual Welding | Single Torch Automation | DynaTwin 200M |

| Labor requirements | 2 welders per beam (typical) | 1 operator per carriage | 1 operator manages dual welds |

| Weld quality consistency | Operator-dependent | Good on straight sections | Strong consistency with oscillation control |

| Setup time | Minimal | 45–90 minutes for rails | 8–12 minutes (magnetic mount) |

| Productivity (meters/hour) | 1.8–2.5 | 4.2–5.1 | 7.3–8.9 |

| Skill requirements | Certified welders | Basic machine operation | Basic machine operation |

| Space requirements | None | Dedicated rail space | Mounts directly to workpiece |

| Maintenance complexity | Torch consumables only | Rails, electronics, drive system | Simplified mechanical system |

A single-torch mechanized carriage improves consistency by controlling travel. A dual torch welding carriage is most valuable when you can exploit twin coverage on suitable seam layouts.

Choose DynaTwin 200M (dual torch) when:

you have parallel seams suitable for two torches in one pass

seam lengths are long and repeatable

fit-up is consistent enough for mechanized runs

output is constrained by welding throughput more than by handling or cutting

Choose single torch automation when:

geometry changes frequently

access is limited and repositioning is constant

one torch path is the real requirement

Choose manual welding when:

low volume, high variability dominates

setup time would exceed welding time

the joint requires continuous manual manipulation

This decision clarity improves RFQ quality and ensures the dual torch welding carriage is applied where it delivers measurable value.

For beams, stiffeners, and long plate assemblies, the DynaTwin 200M supports repeat production where meters per hour and consistent bead profile drive profitability. For related automation tools, browse welding automation solutions.

Trackless mounting is useful for large panels and stiffener work where rail setup and relocation consume time. By reducing operator dependency, a dual torch welding carriage helps lower welding cost per meter in production. A trackless welding carriage can reduce non-productive setup time between stations.

Useful for skids, frames, and structural supports where predictable throughput and reduced rework contribute directly to delivery performance.

Supports long seam work on frames and reinforcement structures where controlled travel speed reduces variation across shifts.

Standards & Industry References:

ISO 3834 welding quality requirements: ISO 3834 standard overview (ISO)

American Welding Society (AWS): AWS (American Welding Society)

Model: Cruxweld DynaTwin 200M

Type: Dual torch automated welding carriage with oscillation

Supported welding processes: MIG / MAG / FCAW (application dependent)

Power input: AC 220V, 50–60 Hz

Control voltage: DC 24V

Motor: DC 24V planetary gear motor (high-torque design)

Travel speed range: 20 – 1900 mm/min

Torch spacing (center-to-center): 300 – 850 mm adjustable

Torch rotation: 0 – 360°

Torch lead/lag angle: ±45° variable

Drive type: Trackless magnetic mount for steel workpieces

Seam guidance: Mechanical guide system for straight seam work

Torch holder diameter range: Ø15 – 50 mm (typical)

Construction: Industrial structure designed for fabrication environments

Typical supply scope

Main carriage assembly

Dual torch holders and clamps

Control interface / control panel

Magnetic base system

Seam guidance components

Power cable set and standard accessories

Tool kit and user documentation

1) What is a dual torch welding carriage used for?

A dual torch welding carriage is used for automated long seam welding to improve speed and consistency.

2) When does a dual torch welding carriage outperform a single torch carriage?

When you can weld two parallel seams in one pass, seam lengths are long and repeatable, and setup time is amortized across production batches.

3) What is oscillation welding and why is it used?

Oscillation (weaving) is used to control bead profile and deposition distribution. In mechanized welding, it improves repeatability on long seams compared to manual weaving variability—when aligned with the qualified procedure.

4) Is DynaTwin 200M trackless or rail-based?

DynaTwin 200M is a trackless, magnetic welding carriage that mounts directly on steel workpieces and does not require rail installation for straight seam work.

5) Which welding processes can the DynaTwin 200M support?

It is commonly used with MIG/MAG/FCAW setups depending on torch and power source configuration and the application requirements.

6) What torch spacing is available?

Torch center-to-center distance is adjustable from 300 to 850 mm, allowing adaptation to different seam layouts.

7) Can one operator run the system?

Typically, one trained operator can handle setup, alignment, and supervision. Material handling support depends on component size and production flow.

8) How do I calculate ROI for a welding automation carriage?

Compare delivered meters per shift and rework rate before and after mechanization, then calculate cost per delivered meter using labor + overhead + rework time.

9) Does it work on rusty or painted surfaces?

Best practice is to clean a narrow travel path for stable movement and consistent guidance, especially for long runs.

10) What should I send for an RFQ or application review?

Send joint photos/videos, thickness range, welding process, target output, and inspection requirements so configuration matches your seam class.