This portable semi-automatic shape cutting machine is suitable for repetitive cutting work where it produces precise and uninterrupted metal cutting following the pattern/template. It can cut any desired shape in less time and with more precision, so overall this profile cutting machine can reduce human interference and increase productivity including less material waste and post-cleaning than manual flame cutting.

| Model | WING1800 |

| Input voltage, V | AC220±10%, 1-Ph, 50/60Hz |

| Modes of cutting | Gas cutting |

| Cutting thickness range, mm | 5-150 |

| Cutting speed, mm/min | 50-750 |

| Diameter of cutting circle, Ø mm | 20-1800 |

| Template mounted on template holder | Any profile within 30mm to 700 mm dia. circle |

| Template mounted on centre shaft | Any profile within 700 mm to 1800 mm dia. circle |

| Length of cutting line, mm | 1650 |

| Magnet tracing roller, Ø mm | 10 |

| Electric motor | DC110V, 24W, 3600r/min |

| Speed control | SCR |

| Control pointer | FWD-OFF-REV toggle switch |

| Speed control | Continuous variable by a rotary knob |

| Tracer | Clockwise & Anti-clockwise |

| Cutter movement | Vertical movement by rack and pinion |

| Template position | Mounted on template holder or central shaft |

| Accuracy, mm | ≤1.5mm |

| Cutting torch | Injector type to suit acetylene/LPG |

| Dimensions (LxWxH), mm | 1190x335x800 |

| Weight, kg | 58 |

Template Preparation

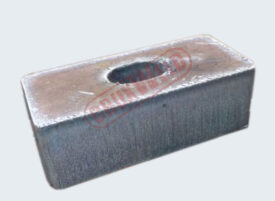

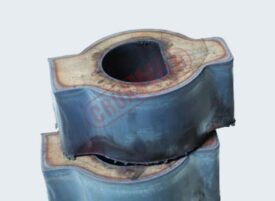

The template should be made of steel sheet with a thickness of at least 3mm so that the magnetic roller can roll around the formwork/template easily and freely.

In the preparation of the template, there should also be allowances for the diameter of the magnetic roller, as well as for the kerf width of the cut.

Load More

After how much time will the start maintenance of the machine