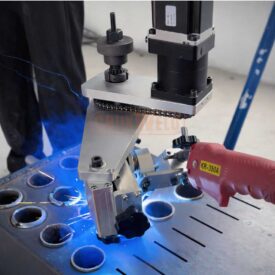

TubeSeal H89 is a tube to tubesheet welding machine built for repeatable circumferential weld cycles on tubesheets. These joints are repeated across large tube patterns and are expected to maintain integrity under thermal cycling, vibration, pressure loading, and long service life. In such conditions, consistency matters more than speed alone.

Manual tube-end welding depends heavily on operator stability and positioning accuracy. Over long production cycles, even skilled work can vary due to fatigue, access limitation, and minor torch angle drift. A tube to tubesheet welding machine solves this by mechanizing the circumferential travel and supporting precise torch alignment, producing repeatable weld cycles across multi-tube assemblies.

Cruxweld TubeSeal H89 is engineered as a portable mechanized tubesheet welding solution built to standardize motion, simplify repeat cycles, and improve execution consistency in demanding fabrication environments.

Cruxweld TubeSeal H89 is a mechanized tube-to-tubesheet welding machine designed to automate the circular travel path around a tube end at the tubesheet interface. Instead of manual hand rotation, the machine provides controlled rotation with programmable cycle logic and fine alignment controls.

This category of equipment is commonly used for:

Heat exchanger tubesheet welding

Boiler tubesheet welding

Tube-box and air-preheater tubesheet work

Maintenance and turnaround welding where repeatable tube-end cycles are required

TubeSeal H89 is part of the broader mechanization approach typically used in advanced fabrication lines and is aligned with the Cruxweld ecosystem under Welding Automation.

Tube ID clamping range: 28–76 mm

Lightweight portable unit: approx. 7 kg

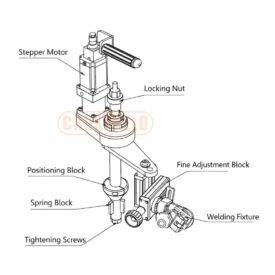

Stepper motor driven rotation with AC 220V supply

Precision torch positioning: X ±60 mm, Y ±60 mm

Torch angle adjustment: ±90°

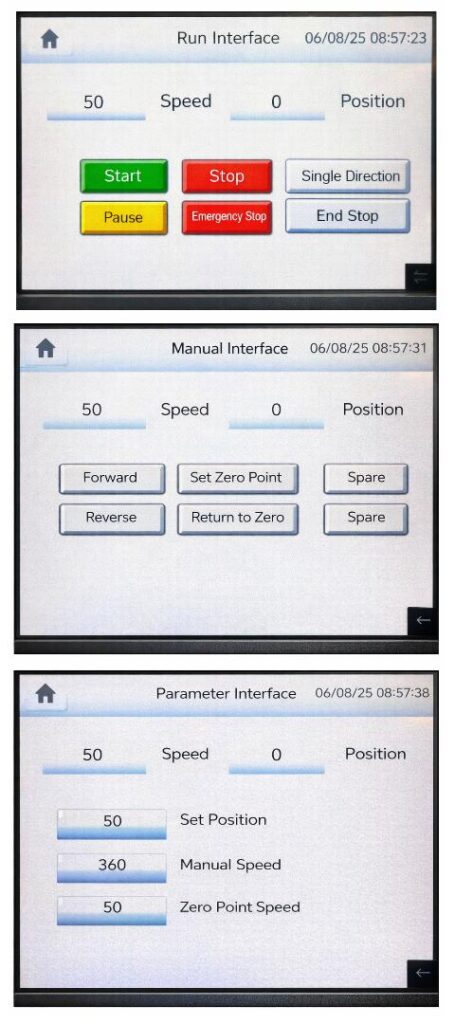

Programmable rotation degrees with return-to-origin workflow

Start / Pause / Stop controls for practical production handling

As a tube to tubesheet welding machine, TubeSeal H89 provides stable rotation and precise torch adjustment to keep weld placement consistent across multi-tube patterns. TubeSeal H89 supports a highly practical tube ID range used across many boiler and heat exchanger assemblies. Clamping is achieved through selectable internal tensioning blocks suited to tube inner diameter, supporting stable mounting during rotation.

In tubesheet fabrication, setup and repositioning time strongly affects output. TubeSeal H89 is designed as a lightweight portable unit (approx. 7 kg), supporting quick movement from one tube position to the next without heavy handling overhead.

The drive system uses a stepper motor actuator to maintain controlled rotation and consistent travel behavior through the programmed cycle. Controlled rotation reduces variability and supports more uniform weld paths over repeated tube patterns.

Correct torch-to-joint alignment is essential for consistent results. TubeSeal H89 provides fine adjustment control:

X-axis: ±60 mm

Y-axis: ±60 mm

This helps align the torch accurately across various tubesheet pitches and access constraints.

Tube protrusion, joint geometry, and workstation access can require torch angle correction. The ±90° angle adjustment supports stable torch approach angles and improved positioning flexibility.

TubeSeal H89 supports arbitrary rotation degree settings for cycle control. This allows customization of rotation patterns to suit qualified procedures and workflow preferences, including multi-turn cycles and return-to-origin behavior for repeat jobs.

Start initiates the synchronized motion cycle

Pause temporarily stops the cycle with resume behavior

Stop halts operation for safe handling

Return-to-origin simplifies repeat cycles and positioning consistency

This makes operation practical in high-density tubesheet work where interruptions and inspection checks can be part of the process.

Heat exchangers demand repeatable tube-end joints to minimize leakage risk and maintain long-term operating stability. A tube to tubesheet welding machine is used to mechanize circular tube-end welds at the tubesheet interface for consistent repeat cycles. In heat exchanger and boiler projects, a tube to tubesheet welding machine improves repeatability across high-density tube patterns.

Boiler tubesheets and tube-box assemblies require consistent execution over large patterns. Mechanized rotation supports uniform weld cycles and repeatable results.

Air preheater assemblies often include repetitive tubesheet joints where stable circular motion improves standardization across the job.

Portable mechanized systems reduce setup effort during shutdown maintenance and repair schedules, where productivity and repeatability are critical.

TubeSeal H89 works within a broader shop ecosystem—typically alongside welding power sources, automation, and support infrastructure. The following internal resources help position TubeSeal H89 in a complete workflow:

Welding Automation – for related mechanized/automatic systems

MIG (GMAW) Welding Equipment – for compatible power sources and shop deployment

TIG (GTAW) Welding Equipment – for procedure-driven workflows where needed

Support – assistance, service flow, and resources

Service Locator – authorized service points

Owners Manuals – manuals and documentation access

Contact Us – enquiry and consultation

For complementary cutting and prep operations in the same facility, refer to Air Plasma Cutting Equipment.

| Model | TubeSeal H89 |

| Product Type | Tube to tubesheet welding machine |

| Tube ID clamping range | 28–76 mm |

| Weight | Approx. 7 kg |

| Drive system | Stepper motor actuator |

| Actuator power supply | AC 220V |

| Torch position adjustment | X: ±60 mm, Y: ±60 mm |

| Torch angle adjustment | ±90° |

| Rotation programming | User-set rotation degrees with return-to-origin capability |

| Control functions | Start / Pause / Stop / Return-to-Origin |

Implementation note: Welding output parameters depend on the connected welding power source and the qualified WPS.

Tubesheet fabrication frequently operates under code-driven or inspection-focused environments (depending on project type and jurisdiction). For welding qualification and procedure context, a widely referenced framework is ASME BPVC Section IX:

ASME BPVC Section IX – Welding, Brazing, and Fusing Qualifications

TubeSeal H89 is designed for mechanized tube-to-tubesheet welding, supporting repeatable circumferential weld cycles in boilers, heat exchangers, and similar assemblies.

TubeSeal H89 supports 28–76 mm tube inner diameter clamping.

Torch alignment is supported via X and Y adjustments (±60 mm each) plus torch angle adjustment (±90°).

Yes. Rotation degrees can be set for different cycle requirements, and return-to-origin behavior supports repeat cycle workflows.

The actuator system operates on AC 220V.

Yes. The unit is designed in a lightweight portable category (approx. 7 kg), supporting frequent repositioning.

No. TubeSeal H89 mechanizes motion and positioning; welding output parameters depend on the connected welding power source and qualified procedure.

Manuals and support resources are available on Owners Manuals and Support, with service access through Service Locator.

Cruxweld TubeSeal H89 brings controlled mechanized rotation, precision torch alignment, and repeatable cycle execution to tubesheet fabrication. Its portable build, wide tube ID support, and programmable workflow make it suitable for repetitive tubesheet joints in heat exchangers, boilers, air preheaters, and industrial maintenance environments—while fitting neatly into the broader Cruxweld Welding Automation lineup.