The field of welding automation is about to experience a major improvement with the launch of portable trackless fillet welding carriages. Developed by Cruxweld, this innovative welding tractor It makes automatic welding easier for a range of uses, including pressure vessels, I-beams, H-beams, and Gadar welding, among others, with the added benefit of stitch welding capabilities. It comes with smart features like a magnetic base, dual guiding rollers, and a speed control system to ensure stability, making it an ideal choice for any welder.

The Cruxweld portable trackless fillet Welding Carriage is an innovative, mobile welding tool that streamlines the welding procedure through automation. This reliable machine guarantees stable and consistent performance thanks to its sophisticated speed control system, ensuring you achieve durable, high-quality welds every time. It is perfect for applications such as rail welding This system is ideal for any project requiring long, even welds, such as those performed with a portable welding machine.

Crafted with user-friendliness in mind, this Cruxweld device allows for precise adjustments to meet your specific requirements. It excels in delivering consistent and strong welds, offering features like reverse fill and crater fill time to ensure the filler metal is applied flawlessly. The Cruxweld WeldyFi is an Automatic Welding Fillet Carriage—a compact yet powerful unit with a magnetic grip and smooth-rolling guides. Together, these features make the welding process simple, providing reliable, high-quality outcomes for a wide range of projects, especially when using a portable welding machine.

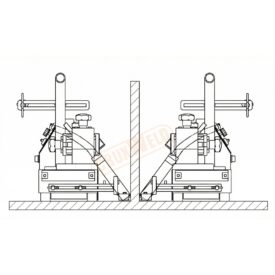

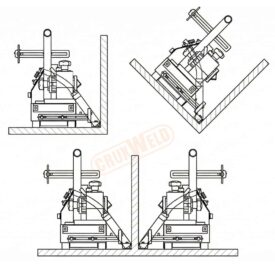

The WeldyFi is a rail-free fillet welding carriage specifically engineered to automate and simplify welding processes without the need for tracks or guides, making it compatible with various welding machines. Its trackless feature allows it to attach easily to metal surfaces using magnetic wheelsThis feature facilitates stable and accurate movement across horizontal, inclined, or vertical seams, ensuring optimal results in welding and cutting tasks. With its compact design and user-friendly control system, WeldyFi guarantees a consistent welding speed and torch positioning, significantly reducing operator fatigue and enhancing weld quality. It is perfect for applications such as tank fabrication, structural steel construction, and shipbuilding, optimizing operations and providing reliable performance in a variety of industrial settings.

The WeldyFi is a rail-free fillet welding carriage specifically engineered to streamline and automate welding processes without the need for tracks or guides. Its trackless nature allows it to magnetically attach to metal surfaces, offering stable and accurate movement across horizontal, inclined, or vertical seams. With a compact design and user-friendly control system, WeldyFi guarantees uniform welding speed and torch placement, significantly minimizing operator fatigue and enhancing weld quality. Perfect for uses such as tank construction, structural steel projects, and shipbuilding, WeldyFi optimizes workflows and provides reliable performance in diverse industrial settings.

The WeldyFi trackless fillet welding carriage is adaptable and can automate various conventional welding methods, especially MIG, MAG (CO2 Welding), and FCAW (Flux-Cored Arc Welding). Thanks to its automated and stable motion control, it performs exceptionally well in ongoing and repetitive fillet welding operations, ensuring consistent bead quality, superior penetration, and a uniform weld finish.

Nonetheless, WeldyFi is primarily utilized with MIG/MAG and FCAW processes, as these techniques greatly advantage from automation, which guarantees accurate torch placement, consistent travel velocity, and minimized imperfections like inconsistent bead shape or inadequate fusion. This feature makes WeldyFi especially appropriate for structural steel manufacturing, storage tank production, shipbuilding, and robust metal constructions that demand dependable and uniform welding results, particularly with a cutting machine. weld quality.

Selecting a trackless welding carriage, such as WeldyFi, provides numerous significant benefits for enhancing welding efficiency and productivity. Because it operates independently of tracks or rails, the time needed for setup is significantly shortened, allowing for swift and simple placement on various metal surfaces, including flat, sloped, and vertical positions. This adaptability enables operators to seamlessly move between weld joints without the need for constant installation of guide rails, conserving precious labor hours and reducing downtime, which is crucial for efficient welding and cutting operations.

Moreover, a trackless welding carriage boosts mobility and flexibility across various job site environments, making it a perfect fit for portable welding applications. Its magnetic wheels securely attach to metal surfaces, ensuring consistent travel speeds and stable torch alignment, which leads to even, high-quality welds, essential for any portable welding setup. This automated approach minimizes human error, enhances overall safety by reducing operator fatigue, and boosts productivity for repetitive fillet welding jobs, especially when using a lightweight design. In the end, a trackless welding carriage such as WeldyFi is an outstanding option for fabricators looking for precision, dependability, and versatility in their welding processes.

WeldyFi a trackless welding carriage provides numerous unique benefits, rendering them highly advantageous for welding tasks.

Quick Trackless Setup: Rapid Installation and Adaptability of the welding machine ensure efficiency on various job sites. Operators can swiftly place the carriage on various weld joints without the requirement for tracks or guide rails. This reduces setup duration and boosts efficiency, particularly for tasks that involve frequent adjustments and diverse welding applications.

Improved Mobility: Fitted with strong magnetic wheels, trackless welding carriages firmly attach to metal surfaces, enabling seamless movement on flat, vertical, or sloped areas. This greatly enhances mobility and adaptability for a variety of welding tasks.

Reliable Weld Quality: Automation guarantees steady torch alignment, uniform travel speed, and consistent bead creation, significantly minimizing human mistakes. It produces repeatable, high-quality welds even during extended welding tasks, thanks to its advanced programme settings.

Decreased Operator Exhaustion: The automation of movement and torch alignment lessens physical stress, enhancing operator comfort and safety in the workplace, particularly for those using portable welding equipment. This allows workers to concentrate more on monitoring and enhancing weld quality instead of performing manual welding activities.

Cost Efficiency: Removing tracks leads to lower costs for equipment and maintenance. By enhancing efficiency, ensuring consistency, and minimizing rework, trackless welding carriages such as WeldyFi ultimately decrease total production costs, proving to be cost-effective over time.

Yes, the WeldyFi trackless welding carriage is designed to execute welds in vertical orientations. It features robust magnetic adhesion and stable guide wheels that allow it to securely attach to metal surfaces, even when positioned vertically. This design guarantees precise torch positioning and smooth movement, eliminating any slipping or wobbling. Whether working on structural beams, storage tanks, or ship hulls, WeldyFi provides reliable speed and accurate control for vertical fillet welding tasks. Its resilient magnetic system is crafted for versatile use at different angles, ensuring consistent performance in demanding conditions and producing high-quality welds regardless of the orientation or position.

The WeldyFi welding carriage requires little training to operate, making it accessible for both novice and experienced welders. Its user-friendly control panel and simple interface make it easy for operators of any skill level to make adjustments and learn quickly. Key features such as speed regulation, torch positioning, and operational parameters are readily available, enabling users to begin working effectively after just a short briefing. Although having some basic welding knowledge is helpful, the WeldyFi is crafted to be accessible, which greatly minimizes training duration and costs. This ease of use speeds up production schedules, boosts productivity, and ensures uniform welding quality, making WeldyFi ideal for teams with limited experience in automation.

| Model | WeldyFi |

| Power Source | AC 110V – 230V, 50/60Hz |

| Power Consumption | 22W |

| Travel Speed | 5 – 1100 mm/min |

| Up/Down Angle | 45° ± 10° |

| Running Angle | ±10° |

| Working Angle Range | 360° |

| Motor | DC 110V, 30W, 4200rpm |

| Guiding System | Fillet tacking guide roller |

| Max Wheel Heating | 70°C |

| Welding Method | Continuous welding |

| Torch Support | Universal with quick attach |

| Driving System | Four-wheel drive rubber tires, motor encoder with planetary gearbox |

| Traction | 4-wheel drive, solid rubber tires |

| Types of Welds | Fillet, V-groove, overhead, out of position, submerged arc |

| Ground Clearance | 5.5 mm |

| Magnet Type | Lifting handle integrated |

| Magnetic Force | 35 kg |

| Torch Holder Diameter | 16 – 25 mm |

| Dimensions (LxWxH) | 220 × 280 × 230 mm |

| Weight | 8.5 kg |