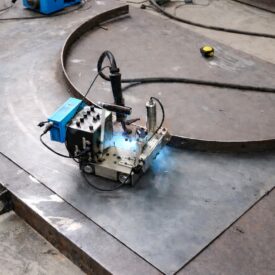

Dynex 5M Trackless Welding Carriage is a trackless, magnetic 4-wheel drive welding carriage with a built-in weaving (oscillation) system and inductive auto-stop. It helps you maintain controlled travel speed, stable torch movement, and selectable weave patterns to match different joint and thickness requirements—especially for fillet welding automation.

Explore more options in our Welding Automation solutions range.

The Dynex 5M Trackless Welding Carriage is ideal for repetitive fillet welding where consistent bead geometry matters. Traditional welding tractors often rely on tracks or rails to guide straight travel. Dynex 5M reduces that dependency with trackless travel and programmable weaving patterns, so you get repeatable weld quality with less setup work.

Trackless operation (no rails needed)

Magnetic 4-wheel drive for stable travel on ferrous workpieces

Five weaving patterns: Linear, Zigzag, Triangular, Circular, Weaving

Digital control for speed, swing, and pause time

Inductive auto-stop to stop at weld end

Detachable controller for easier operation

Dynex 5M is designed for trackless movement, which reduces preparation time—especially useful in job shops where multiple assemblies are welded daily.

The 4-wheel drive design supports stable movement on steel workpieces. This helps maintain consistent travel during long seams and repetitive fillet runs—improving weld appearance and reducing rework.

Dynex 5M supports five oscillation patterns. Choosing the right pattern improves bead width control, side-wall fusion, and repeatability.

Best for: uniform seams where weaving isn’t required

Why: stable travel and neat bead profile

Best for: wider fillet welds

Why: improves side-to-side coverage and toe fusion

Best for: heavy structural components

Why: supports deeper penetration style passes

Best for: curved surfaces and pipe-like geometry

Why: smoother movement where geometry changes

Best for: wide seams or overlapping passes

Why: consistent cap appearance with controlled coverage

Dynex 5M works well with most setups used with MIG (GMAW) welding machines, making it easy to integrate into your existing production line.

Dynex 5M allows practical control over parameters that influence bead shape:

Travel speed

Swing speed and swing angle

Left/right pause time (dwell control)

Deviation setting

This makes bead geometry more repeatable across operators and shifts—helping reduce rework and improving consistency on production batches.

Inductive auto-stop helps the carriage stop at the end of the weld path, reducing overrun and making long-run welding more manageable for the operator.

For long seams, the Dynex 5M Trackless Welding Carriage helps reduce operator fatigue and improves repeatability. Dynex 5M is a strong fit for long-seam and fillet welding automation in:

Shipbuilding: stiffeners, ribbed plates, long seam work

Structural steel & bridges: beams, frames, reinforcement seams

Tank fabrication: continuous fillet welds on large steel structures

For code-driven industries (pressure vessels / critical fabrication), buyers often refer to recognized standards such as ASME (external reference).

Dynex 5M carriage unit

Detachable controller

Torch clamp and mounting accessories

Standard cables and basic tools (as supplied)

No. Dynex 5M is a trackless welding carriage designed to move without rails or tracks, helping reduce setup time.

Dynex 5M supports five patterns: Linear (Straight), Zigzag, Triangular, Circular, and Weaving (Wave) to match different joint needs.

The carriage supports a welding speed range of 150–2000 mm/min, suitable for both precision and production welding.

Yes. Dynex 5M is widely used for fillet welding automation where consistent travel speed and repeatable bead geometry are required.

Dynex 5M supports a universal torch clamp diameter range of 16–50 mm, compatible with many standard torches.

Yes. Dynex 5M includes an inductive auto-stop mechanism that helps stop the carriage at the end of the weld path.

Request pricing and availability for the Dynex 5M Trackless Welding Carriage based on your joint type and thickness. To recommend the best configuration quickly, share:

Material and thickness

Joint type (fillet size / leg length)

Welding position (flat/vertical)

Torch type and power source details

Approximate welding length per day

Contact Cruxweld for quotation

Dynex 5M Trackless Welding Carriage with magnetic 4-wheel drive, 5 weaving patterns, digital control and auto-stop for faster, consistent fillet weld automation.

Product SKU: DYNEX-5M

Product Brand: Cruxweld

| Specification | Details |

|---|---|

| Model | Dynex 5M |

| Welding Speed | 150–2000 mm/min |

| Weaving Patterns | Linear, Zigzag, Triangular, Circular, Weaving |

| Operation Type | Trackless / Magnetic 4-Wheel Drive |

| Swing Angle | ±15° |

| Dwell/Pause Time | 0–2.5 seconds (Left/Right) |

| Torch Adjustment | 60 mm (Up/Down/Forward/Backward) |

| Torch Clamp Diameter | 16–50 mm |

| Oscillation Precision | ±0.1 mm |

| Protection Class | IP54 (Dust & Water Resistant) |

| Power Input | 110V, 50/60Hz |

| Power | 17W |

| Dimensions (L×W×H) | 59 × 38 × 41 cm |

| Gross Weight | 16.5 kg |