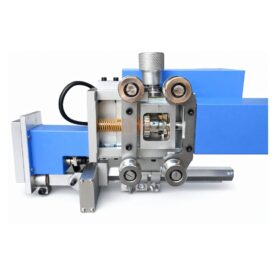

The Cruxweld DynaSwing 100K is a high-performance magnetic oscillating welding carriage built for repeatable weld quality on long seams. Its rack & pinion drive ensures steady travel—ideal for vertical welding where slippage can cause defects. The linear torch oscillator supports trapezoid, triangle, and straight-line patterns for uniform heat and bead consistency. With a magnetic rigid rail track, it’s suitable for horizontal, vertical, and overhead welding automation.

Explore our full range of welding automation solutions to build a complete mechanised setup for vertical and overhead welding.

Revolutionize your welding process with the Cruxweld DynaSwing 100K, a high-performance magnetic oscillating welding carriage built for consistent, repeatable welds in demanding industrial environments. Whether you’re welding long seams on structural steel, heavy plates, or fabrication assemblies, this automatic welding carriage with oscillator helps you improve bead uniformity, reduce rework, and increase productivity. This page covers the DynaSwing 100K magnetic oscillating welding carriage for vertical, horizontal and overhead welding automation.

The DynaSwing 100K combines three things industrial buyers care about most:

Stable travel motion (rack & pinion drive)

All-position operation (magnetic rigid rail for vertical & overhead)

Controlled weaving/oscillation (trapezoid, triangle, straight-line paths)

If you’re looking for a reliable vertical welding carriage that can also handle horizontal and overhead applications, DynaSwing 100K is a strong upgrade from manual welding and inconsistent carriage setups.

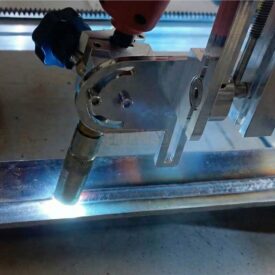

Many welding carriages struggle in vertical applications because friction-based drive systems can slip or lose traction. The DynaSwing 100K uses a rack and pinion drive system, engineered to deliver steady and consistent motion for both vertical and horizontal welds. This means smoother travel, better arc stability, and more consistent penetration throughout the weld seam.

Travel speed range: 30 – 1100 mm/min, giving you flexibility to match different WPS requirements and materials.

DynaSwing 100K works well with common processes like MIG/MAG, and for best performance we recommend pairing it with a suitable MIG welding machine (GMAW power source) as per your WPS, wire diameter, and plate thickness.

The DynaSwing 100K runs on a magnetic rigid rail track system with permanent magnets. The track creates a strong holding force and allows the system to be used vertically—a major advantage for structural fabrication and long vertical seams.

Because the rail uses permanent magnets, it provides secure placement and confidence during operation, including applications where overhead positioning is required (as mentioned in the prominent factors).

To achieve better side-wall fusion and a uniform bead profile, the DynaSwing 100K includes a linear torch oscillator that produces controlled side-to-side movement of the torch/electrode. This helps distribute heat evenly and reduce defects like undercut or lack of fusion. The DynaSwing 100K magnetic oscillating welding carriage combines rack & pinion travel with controlled weaving for consistent bead quality.

Available oscillation paths:

Trapezoid

Triangle

Straight line

This makes it ideal for fillet welding and other joints where weaving is required for consistent coverage.

If you also need a non-rail option, compare this model with our trackless welding carriage (Dynex 5M) for different site conditions and joint types.

The DynaSwing 100K includes a multifunction LED display with intuitive control settings for precise adjustments and repeatability.

Key adjustable controls include:

Choose walk direction: Left / Right

Swing speed: 0–100

Swing angle: ±15°

Walk speed setting: 0–130 cm/min

Dwell time (left/right stay): 0–2.5 sec

Deviation position: 0–±8°

Swing model selection: Five modes

The DynaSwing 100K is designed for:

Fillet welding

Downward welding

Vertical welding

It also mentions overhead welding capability in the prominent factors, making it suitable for all-position job requirements where magnetic rail installation is needed.

Carriages with oscillator facilities are often compatible with multiple welding processes such as:

MIG/MAG

TIG

Submerged Arc Welding (SAW)

This versatility makes DynaSwing 100K a practical solution for fabrication shops, production units, and heavy engineering applications.

For long seam jobs, this magnetic oscillating welding carriage improves repeatability and reduces rework in fabrication. If you are searching for a magnetic oscillating welding carriage to improve weld repeatability in production or fabrication, DynaSwing 100K is ideal for:

Long seam welding on structural steel

Fabrication work requiring vertical welding automation

Workshop jobs where you need consistent weaving for fillets

Heavy plate joining where controlled travel speed improves penetration

Jobs where operator exposure to arc heat and fumes needs reduction

Repeat weld procedures where stable motion improves quality and reduces rework

Oscillation helps distribute heat evenly and reduces the risk of defects such as undercut or lack of fusion. By maintaining steady travel and oscillation, the magnetic oscillating welding carriage helps reduce defects like undercut and lack of fusion.

The DynaSwing 100K helps eliminate over-welding and reduce filler metal waste, improving cost-effectiveness for continuous production work.

By automating torch movement and travel, operators are shielded from direct heat and fumes—improving comfort, safety, and productivity.

With compact dimensions and 8.5 kg weight, the carriage is portable and easy to deploy on-site or in-shop.

For reference, you can also read TWI’s guide on the difference between mechanised, automated and robotic welding to understand how welding carriages improve consistency and productivity.

The DynaSwing 100K welding carriage package includes:

Welding carriage

Magnetic rail (3.6 m)

Power cord (16 m)

Hex wrench

Fuse (2A)

Cross slide assembly

Cable anchor

Operator’s manual

Request a quote for the DynaSwing 100K magnetic oscillating welding carriage and get a recommendation as per your job requirement.

Want pricing, delivery, or a quick recommendation? Click here to request a quote from Cruxweld.

DynaSwing 100K supports trapezoid, triangle, and straight line oscillation paths.

It uses a rack and pinion drive system for steady and consistent motion in vertical and horizontal welding.

The travel speed range is 30 – 1100 mm/min.

Yes. The permanent magnetic track enables vertical installation, and the rack & pinion drive ensures stable motion.

The track uses permanent magnets to create strong holding force.

Supply voltage required is AC 220V, 50/60 Hz.

Torch diameter supported is 16 – 22 mm.

The carriage can be used for MIG/MAG, TIG, and submerged arc welding (SAW) applications.

Standard scope includes carriage, 3.6 m magnetic rail, 16 m power cord, fuse, tools, cross slide assembly, cable anchor, and manual.

| Model | DynaSwing 100K |

| Supply Voltage | AC 220V, 50/60 Hz |

| Swing Motor | DC 24V |

| Drive System | Rack and pinion |

| Travel Speed | 30 – 1100 mm/min |

| Torch Adjustment (Up/Down) | 50 mm |

| Torch Adjustment (Front/Rear) | 60 mm |

| Range of Working Angle | ±45° |

| Range of Adjusting Angle | 10° |

| Swing Speed | 0–100 |

| Swing Angle | ±15° |

| Dwell Time (Left/Right) | 0–2.5 sec |

| Deviation Position | 0–±8° |

| Oscillation Path | Trapezoid, Triangle, Straight Line |

| Tracking Mode | Rail |

| Welding Positions | Fillet, Downward, Vertical (Overhead capability also stated) |

| Torch Diameter | 16 – 22 mm |

| Pulling Force (Horizontal) | 350 N |

| Pulling Force (Vertical) | 150 N |

| Dimensions | 440 × 290 × 300 mm |

| Weight | 8.5 kg |