In the high-stakes world of heavy industrial fabrication, manual inconsistency is the greatest enemy of profitability. The WeldOrbit 360 Automated Oscillation Carriage is the ultimate answer to the industry’s most pressing challenges: the skilled labor deficit and the demand for zero-defect quality. This is not just a tractor; it is a high-performance welding automation platform that transforms your existing power sources into a precision-engineered production powerhouse.

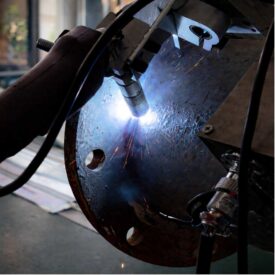

By integrating advanced pendulum oscillation with a 3-in-1 multi-process capability, the WeldOrbit 360 Automated Oscillation Carriage allows your shop to handle MIG welding, high-speed plasma cutting, and heavy-duty oxyfuel beveling with a single, portable unit. Whether you are fabricating pressure vessels for nuclear power or long-distance oil pipelines, this system provides the mechanical rigidity and parametric control necessary for flawless, X-ray quality execution.

The WeldOrbit 360 Automated Oscillation Carriage is specifically engineered to replace the slow, fatigue-prone movements of manual welding on circular and longitudinal structures. By utilizing a low center of gravity and a high-strength magnetic wheel drive system, this carriage ensures rock-solid stability across all welding positions—flat, horizontal, vertical, and overhead.

The primary technical differentiator of the WeldOrbit 360 Automated Oscillation Carriage is its sophisticated pendulum (radial) oscillation module. Unlike basic linear tractors that move the torch in a simple straight line, our pendulum mechanism swings the arc in a radial sweep. This motion perfectly replicates the professional “walking the cup” technique used by elite pipe welders to minimize fatigue and maximize bead width.

The result is exceptional sidewall fusion and a perfectly uniform bead profile that meets the most stringent international (https://www.iso.org) standards for structural integrity and leak prevention. By automating the weaving pattern, you eliminate the human variability that often leads to lack of fusion or slag inclusions in deep-groove joints.

Automation with the WeldOrbit 360 Automated Oscillation Carriage does not replace your workforce; it serves as a force multiplier. In today’s competitive market, finding certified high-pressure welders is an increasing bottleneck for growth. By automating the torch manipulation and travel speed, a single operator can supervise three or even four carriages simultaneously.

This shift allows your most experienced technicians to focus on high-value oversight and complex project setup while the machine handles the high-heat, repetitive tasks with $100\%$ consistency. Field data indicates that shops moving to this level of mechanization see a workforce efficiency gain of up to $400\%$.

Manual manipulation requires constant stops, starts, and repositioning, which are the primary sources of weld defects and wasted time. The WeldOrbit 360 Automated Oscillation Carriage is built for continuous operation at a $100\%$ duty cycle. By eliminating operator fatigue and the need for frequent breaks, fabrication facilities report productivity increases of $300\%$ or more compared to traditional manual arc processes. Faster cycle times mean you can bid on larger contracts and meet tighter delivery windows with total confidence.

Maximize your capital equipment ROI by utilizing a single tool for your entire fabrication workflow. The WeldOrbit 360 Automated Oscillation Carriage features a universal torch mount that allows for process changeovers in minutes, reducing the need for multiple specialized machines.

Pair your carriage with our professional MIG welding systems to deliver high-deposition rates that manual welders simply cannot sustain over a full shift. The integrated Silicon Controlled Rectifier (SCR) system maintains a constant travel speed and contact-tip-to-work distance (CTWD). This level of control is vital for stabilizing the arc and ensuring deep, consistent penetration on thick-walled pressure vessels and structural frames.

When precision is required on non-ferrous metals like stainless steel, aluminum, or copper, simply swap the welding torch for a plasma setup. Integrating an air plasma cutting machine with the WeldOrbit 360 Automated Oscillation Carriage creates a motorized cutting powerhouse. You can achieve high-speed cuts (up to $1150$ mm/min) with a narrow kerf and a significantly reduced Heat Affected Zone (HAZ), which preserves the metallurgical properties of the base metal and virtually eliminates post-cut grinding time.

For carbon steel plates up to $100$ mm thick, the carriage is fully compatible with standard oxyfuel cutting torches. The adjustable torch holder allows for motorized beveling at angles up to $45^\circ$, automating the edge preparation process required for high-quality multi-pass welding. By cutting and beveling in a single motorized pass, you ensure a consistent land and root face, which is the essential foundation for a defect-free automated root pass.

The versatility of the WeldOrbit 360 Automated Oscillation Carriage is most apparent in applications that are notoriously difficult to perform manually with any degree of repeatability.

Flange connections are the backbone of high-pressure industrial piping systems. Manual welding often results in uneven heat distribution due to the heavy heat sink of the flange compared to the pipe wall. The WeldOrbit 360 Automated Oscillation Carriage uses its pendulum weaving module to bridge these gaps perfectly. It ensures a smooth transition and leak-proof connections that pass X-ray and Ultrasonic testing (UT) every time, meeting the highest quality acceptance levels.

In the construction of massive storage tanks and chemical vessels, the WeldOrbit 360 Automated Oscillation Carriage serves as a specialized automatic girth welder. Its magnetic wheel drive allows it to traverse the circumference of the tank with slip-free precision, even on vertical walls. This eliminates the need for expensive custom jigs, temporary tack welding, or track drilling, allowing for rapid deployment on site and significantly faster project completion for oil and gas infrastructure.

Long vertical seams and hull reinforcements require absolute bead uniformity to withstand harsh marine environments and mechanical stress. The magnetic stability of the WeldOrbit 360 Automated Oscillation Carriage ensures that the torch remains perfectly aligned without sagging. The system’s low center of gravity provides the rigidity needed for high-amperage multi-pass welding, delivering the structural integrity that modern shipyards demand.

The WeldOrbit 360 Automated Oscillation Carriage puts full control of the welding arc at your fingertips. Through the ergonomic remote control unit, operators can fine-tune every variable to match the specific Welding Procedure Specification (WPS).

Five Precision Weaving Modes: The system features five distinct oscillation patterns—including Square Wave (Trapezoidal), Triangle, and Multi-Step. This allows you to adapt the heat distribution to the material thickness and joint prep, ensuring perfect tie-in at the toes of the weld on every pass.

Independent Dwell Time Control: You can set independent left and right dwell times ($0 \sim 2.5$ sec) to ensure the weld pool bridges the joint geometry perfectly, preventing common defects such as undercut and lack of fusion.

Stepless Oscillation Speed: Adjust the speed of oscillations from $0 \sim 120$ mm/min to achieve the desired pitch and appearance of the weld bead, whether you are performing a root pass or a wide cosmetic cap.

Investing in the WeldOrbit 360 Automated Oscillation Carriage isn’t just a technical upgrade; it’s a strategic business decision that delivers immediate financial benefits.

Fast Payback Period: Most high-volume fabrication shops achieve full Return on Investment (ROI) in less than 12 months through labor savings and increased throughput.

Massive Reduction in Material Waste: Manual welding often leads to “over-welding”—depositing 20 percent more filler metal than necessary to compensate for inconsistent fit-up. The precision of our carriage ensure only the exact amount of filler is used, saving you thousands in annual consumable costs.

Eliminate Costly Rework: The cost of re-welding a failed joint is 3 to 4 times higher than the original weld cost. Automation brings your defect rate close to zero, protecting your reputation and your profit margins.

Enhanced Operator Safety: By moving the operator away from the direct arc and hazardous fumes using the 20-meter remote control, you significantly improve workplace ergonomics. This leads to higher employee morale and lower insurance premiums for your facility.

Yes. While the high-strength magnetic wheels require a ferrous (iron-based) surface to adhere, the carriage can be used on non-ferrous materials like aluminum and stainless steel by utilizing a dedicated track or rail system. The MIG and Plasma processes are fully compatible with these materials, providing the same high-speed precision.

Pendulum oscillation swings the arc in a radial arc relative to a pivot point. This provides superior heat distribution at the “toes” of the weld bead, which is critical for preventing undercut and slag inclusions in deep-groove joints. It is the only way to achieve master-level cosmetic and structural quality at machine speeds.

Absolutely. The WeldOrbit 360 Automated Oscillation Carriage utilizes a high-durability wired remote control with a standard 20-meter cable. This ensures zero signal interference from high-frequency arcs often found in Plasma or TIG operations, providing 100% reliable control even in the harshest industrial conditions.

Yes. The torch holder is adjustable up to 45 degrees, allowing you to perform square cuts, V-grooves, and complex bevels in a single motorized pass. This ensures your joint geometry remains identical across the entire length of the workpiece, a prerequisite for X-ray quality root passes.

Don’t let manual inconsistency and labor shortages limit your company’s growth. The WeldOrbit 360 Automated Oscillation Carriage is the professional choice for fabrication shops that refuse to compromise on quality, safety, or throughput.

Take Action Today:

Explore our full range of industrial MIG welding systems.

Upgrade your cutting capabilities with Air Plasma Cutting equipment.

Get a customized quote for your next welding automation project.

Input Voltage: 220V AC, 50/60 Hz

Welding Speed: 50 – 750 mm/min

Cutting Speed: 50 – 1150 mm/min

Up/Down: 30 mm

Forward/Backward: 360°

Left/Right Dwell Time: 0 – 2.5 sec

Oscillation Speed: 0 – 120 mm/min

Oscillation Distance: ±60 mm

Working Angle: 0 – 45°

Cut/Bevel Angle: Variable up to 45°

Moving Mode: Four-wheel drive

Swing Motor: DC24V 18RPM

Oscillating Motor: Stepper motor

Drive Mode: Magnetic wheel drive

Dimensions: 250 × 400 × 210 mm

Weight: 12.5 kg

Welding carriage – 1 pc

Oscillator – 1 pc

Remote control – 1 pc

Cable holder – 1 pc

Power supply with 2.5 m cord – 1 pc

Welding torch signal cable 0.5 m – 1 pc

Connection cable for welding machine 20 m – 1 pc

Fuse 3A – 2 pcs

Set of Allen keys – 1 pc

Operating instructions – 1 pc