DuoFlex 20K is a 2 in 1 spot and seam welder designed for sheet metal fabrication where both spot welding and seam welding are required. 2 in 1 spot and seam welder DuoFlex 20K is a compact resistance welding solution for sheet metal fabrication, combining handheld spot welding and roller seam welding in one system. The digital microcomputer controller allows accurate parameter setting and stores multiple welding programs for repeatable output. Powered by a 20 kVA thyristor-based DC system, it delivers stable performance for job shops and production use.

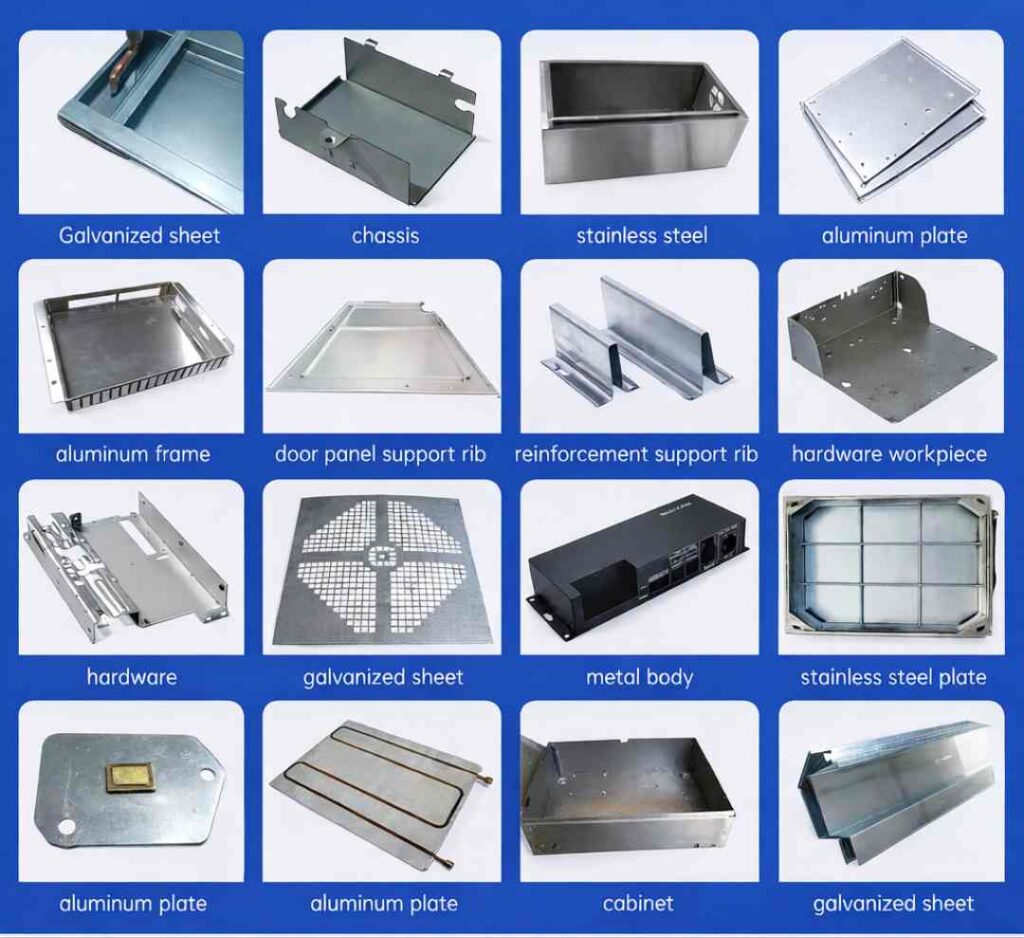

DuoFlex 20K is built for workshops that need fast spot weld points and clean continuous seams without maintaining two separate machines. If your fabrication work includes cabinets, enclosures, panels, ducts, channels, frames, stainless fabrication, or light industrial assemblies, this 2-in-1 platform helps improve productivity while keeping weld output consistent across shifts and operators.

In daily fabrication, two types of joining are most common:

Spot Welding for quick tack joints and repeated weld points on lap joints

Seam Welding for continuous joints where finish must look neat and joints must remain consistent along straight or curved edges

This 2 in 1 spot and seam welder is ideal for cabinets, enclosures, panels, HVAC ducts, frames, and production assemblies. Many workshops use separate systems for these tasks, which increases floor space, training time, and setup variation. DuoFlex 20K combines both processes into a single solution: a handheld single-sided spot welding gun plus a handheld roller seam welding option, powered by a 20 kVA thyristor-based DC system and controlled through a digital microcomputer controller for accurate settings and repeatable results.

To explore more solutions under resistance welding, browse the full category:

https://www.cruxweld.com/category/resistance-welding-equipments/

Spot welding is one of the most used joining methods for sheet metal jobs where speed and repeatability matter. The handheld single-sided spot gun in DuoFlex 20K is ideal for fast weld points in:

sheet metal assemblies and panels

steel cabinets and industrial enclosures

stainless fabrication jobs and kitchenware components

light frames, channels, brackets, and supports

doors, wardrobes, and fabrication sub-assemblies

Because it is handheld, operators can position the gun directly on the joint area without moving or re-clamping heavy workpieces repeatedly. This is especially useful in job shops where products change daily and production fixtures need flexibility.

If your customer needs other spot welding formats and capacities, check our Spot Welder range:

https://www.cruxweld.com/category/resistance-welding-equipments/spot-welder/

When a job requires a continuous seam line, a roller seam welding option becomes important. Roller seam welding is typically preferred when:

you want a continuous joint rather than isolated points

the product requires a cleaner visual finish

the seam must remain consistent across batches

your production line needs faster, uniform seam welding

the joint path is straight or curved and needs controlled movement

The handheld roller seam option is useful for many sheet metal products where a continuous joint appearance improves the overall quality perception for the end buyer. It helps achieve consistent seam formation on repeated production runs when parameters are maintained correctly.

Along with the standard 2-in-1 setup, DuoFlex 20K can be supplied with an optional double-sided handheld spot welding gun with upper and lower copper electrodes. This style is preferred when the customer can access both sides of the joint and wants a tong-type clamping action for stronger and more consistent spot weld points.

the joint can be accessed from both sides

stronger, cleaner spot weld nuggets are required

repeat production needs consistent pressure and alignment

fixture-based welding is used for repeated parts

the application demands stable clamping before current flow

sheet metal lap joints with both-side access

cabinet bodies, enclosures, frames, channels

fabrication jigs and fixtures for repeated welding points

ducting and light industrial production lines

A 2 in 1 spot and seam welder is ideal for cabinets, enclosures, panels, ducts, frames, and other sheet metal assemblies. This optional accessory is a strong choice for customers who want consistent spot welding output across operators and batches, especially where pressure and electrode alignment must remain stable.

Buyers prefer a 2 in 1 spot and seam welder to reduce floor space, simplify operation, and maintain repeatable weld quality with stored programs. In resistance welding, most inconsistent quality comes from variation in timing and operator settings. DuoFlex 20K includes a digital microcomputer controller that supports accurate adjustment and repeatable welding cycles. It helps maintain consistent output by allowing the operator to set key parameters and store multiple welding programs for repeated jobs.

Weld time – controls how long current flows through the joint

Squeeze time – controls clamping time before welding begins

Pre/Post timing – helps stabilize the cycle and repeatability

Weld current/heat control – adjusted based on thickness and joint design

Once suitable settings are finalized for a job, the memory feature helps repeat the same output without daily re-tuning. This reduces setup time, avoids inconsistency between operators, and supports batch production.

DuoFlex 20K supports continuous and pulsed welding modes. These modes help manage different job conditions, especially when sheet thickness varies or controlled heat input is required.

Continuous mode is commonly used for standard spot welding cycles and seam welding where stable output is required.

Pulsed mode is helpful when controlled heat input is needed to reduce overheating on thinner sheets or sensitive joints.

In practical fabrication, pulsed mode helps control marking and heat distortion on thin sheet applications, while continuous mode is the preferred choice for regular production.

DuoFlex 20K is designed for job shops and production environments where sheet metal welding is regular and both spot and seam capability is required in a compact setup.

sheet metal fabrication shops

electrical panel and enclosure manufacturers

HVAC and ducting fabricators

stainless fabrication workshops

cabinet, furniture frame, and light structure makers

maintenance and repair teams requiring portable handling

enclosures and cabinets

ducting components

light frames and brackets

channels and supports

stainless assemblies

curved seam products where seam roller is useful

repeated spot joints in fixtures and production assemblies

DuoFlex 20K uses a thyristor-based DC power source designed for stable resistance welding performance. Stability supports:

consistent weld nugget formation

repeatable output between weld points

reduced variability across operators

smoother production cycles

When combined with digital timing control and program memory, the output becomes more predictable for daily fabrication work.

For export orders and long-distance shipments, DuoFlex 20K can be dispatched in a strong export-grade wooden crate designed to protect the machine from impact, vibration, and handling shocks during transit.

heavy-duty wooden crate protection

suitable for domestic and international shipments

helps reduce transit damage risk

recommended for sea and air freight movement

For pricing, delivery timeline, optional double-sided spot gun availability, and export wooden packing, contact us here:

https://www.cruxweld.com/contact-us/

For a general overview of resistance spot and seam welding, you can refer to the American Welding Society (AWS):

https://www.aws.org/

| Rated Capacity | 20 kVA |

| Input Supply | AC 415V ±15% |

| Frequency | 50/60 Hz |

| Max Welding Capacity | 1.8 + 1.8 mm |

| No Load Voltage (Max.) | 11 V |

| Rated Primary Current | 70 A |

| Welding Time Range | 1–999 ms |

| Welding Current Range | 1–2000 A |

| Secondary Unload Voltage | 7.6 – 12.8 V |

| Controller | Digital microcomputer controller |

| Pre / Post Welding Time | 0–999 ms adjustable |

| Display | Digital LCD |

| Memory Capacity | Stores multiple welding parameters |

| Welding Modes | Continuous, Pulsed |

| Welding Method | Resistance Welding |

| Operating Temperature | -10°C to 50°C |

| Insulation | H |

| Transformer Cooling | Air cooled |

| Cable Length (Earth / Output) | 3 m / 3 m |

| Controller Weight | 2.5 kg |

| Gun + Control Cable Weight | 8.5 kg |

| Dimensions (L×W×H) | 520 × 800 × 680 mm |

| Machine Weight | ~82 kg |

Yes, DuoFlex 20K works as a 2 in 1 spot and seam welder by combining handheld spot welding and roller seam welding in one setup.

The rated capacity is 20 kVA, suitable for common sheet metal fabrication work.

The unit operates on AC 415V ±15%, 50/60 Hz.

The maximum welding capacity is 1.8 + 1.8 mm for lap joints as per specification.

Yes. The digital microcomputer controller stores multiple welding parameters in memory, which helps repeat jobs with consistent results.

Welding time range is 1 to 999 milliseconds (ms), allowing fine control for different materials and thicknesses.

The welding current range is 1–2000 A, which supports different welding requirements within the machine’s application range.

Yes. DuoFlex 20K supports continuous and pulsed welding modes. Pulsed mode is often used for better heat control, especially on thin sheet.

It is used for true spot welding from both sides using upper and lower electrodes. It clamps the joint from both sides and can provide stronger, cleaner, more consistent spot weld nuggets in production.

Yes. For export orders, DuoFlex 20K can be dispatched in a strong export-grade wooden crate for safe worldwide shipping and handling protection.

Yes. The portable design and programmable controller make it suitable for job shops, repeat orders, and production environments where consistency matters.

Share your material type, sheet thickness, joint design, and production requirement. Based on that, you can select the best combination: 2-in-1 standard setup, roller seam option, and optional double-sided spot gun if required.